Ultrasonic welding is an industrial technique in which high-frequency acoustic vibrations are applied to workpieces held together under pressure to create a solid-state weld. It is mostly used for plastics, and for joining dissimilar materials.

Ultrasonic welding is an industrial technique in which high-frequency acoustic vibrations are applied to workpieces held together under pressure to create a solid-state weld. It is mostly used for plastics, and for joining dissimilar materials.

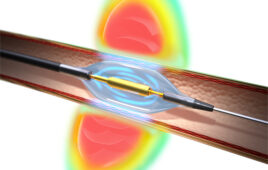

High-frequency vibrations are applied to two parts or layers of material by a vibrating tool, such as a sonotrode or horn. Welding occurs as the result of heat generated at the interface between the parts or surfaces.

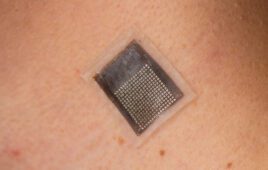

This technique is fast, efficient, non-contaminating, and requires no consumables. In addition to welding, ultrasonic processes can be used to insert, stake, stud-weld, degate, and spot-weld thermoplastics as well as seal, slit, and laminate thermoplastic films and fabrics. Ultrasonic components can be easily integrated into automated systems.