The challenge of integrating 3D printing into the surgical space boils down to two problems – cost and access to efficient technology. Materialise is trying to bridge that gap with the launch of its suite of software and 3D printing services, which were introduced during American Association of Orthopaedic Surgeon’s Annual Meeting last week.

(Credit: Materialise)

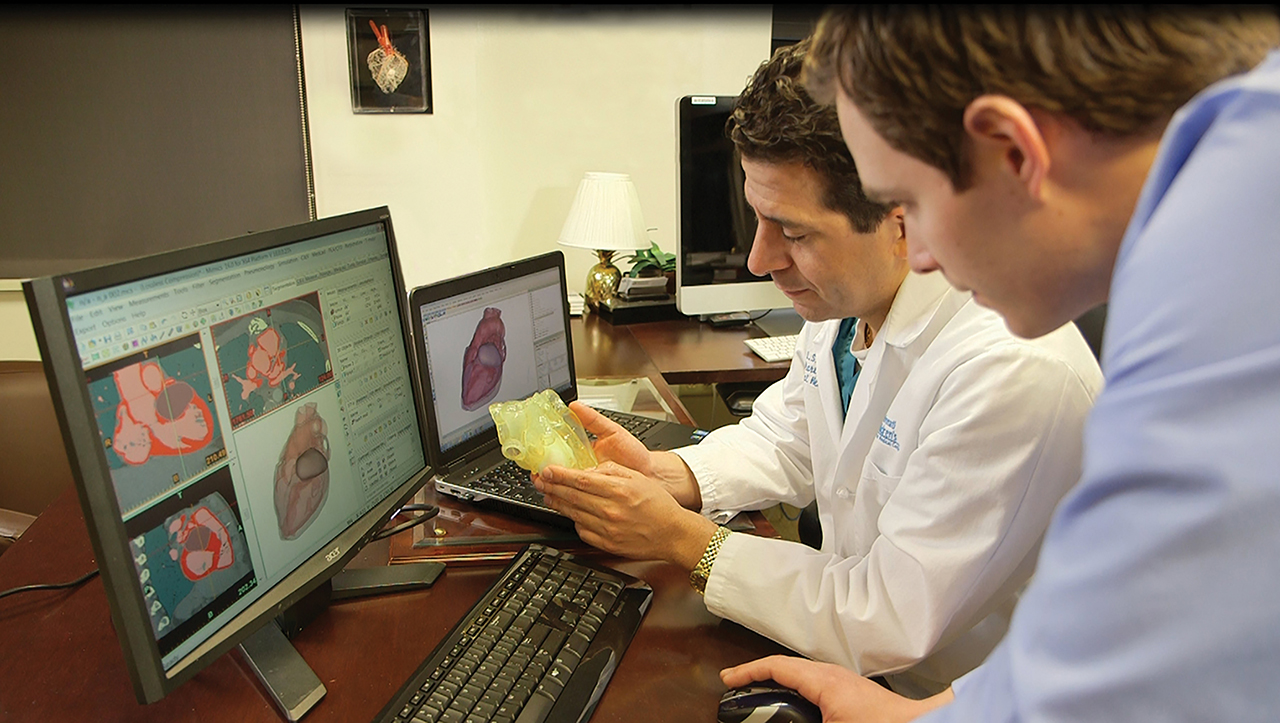

This technology combines a clinician focused version of the complex engineering data software that uses imaging files to design an anatomical model, which may be printed on whichever 3D printer a hospital chooses to work with. Theoretically, it will mean surgeons from training centers to community hospitals will be able to prepare for cases with a patient-specific anatomical model. “The more I talk to surgeons, the more tell me there really is a big difference in having a physical model in your hand,” Pieter Slagmolen, product manager at Materialise Mimics Care Suite, says. “It has not been an easy technology to implement, even though we are doing a lot of efforts to make it so, but (surgeons) are really seeing the value of it.”

While the end goal is to make 3D printing accessible across the industry, Slagmolen says the FDA and 510K cleared software will most likely trickle down from training centers to small facilities, especially after more data is released that shows improved outcomes and case efficiency. “There is some data out there already, but it is still in development,” Slagmolen said.

This article originally appeared in Surgical Products.