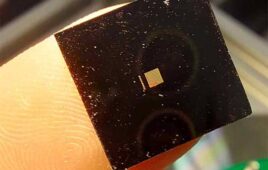

An enzyme-propelled nanorobot: Urease-coated nanotubes turn into a propulsion system in a urea-containing liquid because the enzyme breaks down the urea into gaseous products. Since the tubes always have small asymmetries, the reaction products generate a current in the fluid which propels them out of the tube like a jet. [Photo from MPI for Intelligent Systems]

Two types of propulsion systems were created. One was powered by bubbles that are oscillated by ultrasound, while the other one was powered by an enzymatic reaction that would propel a nanoswimmer. The researchers used the idea of jet propulsion to create these nanorobots.

Underwater nanorobots are single-walled nanotubes that are made of silicon dioxide and are 220 nm wide. With its small size, nanorobots were unable to propel itself in the water.

Researchers coated the inside or inside and outside of a nanotube with the enzyme urease. The urea breaks down into ammonia and carbon dioxide and the chemical reaction creates a current in the fluid that propels the urea from the tube. The thrust is created because of the uneven distribution of the urea inside of the nanotube and microswimmers propel in the opposite direction at a speed of 10 micrometers per second.

Even though the chemical drive is not a new method, this reaction has created the smallest jet propulsion in the world.

“Our previous record, which is still in the Guinness Book of Records, was around 3 times bigger,” said Samual Sanchez, leader of the Smart NanoBioDevices Group at the Max Planck Institute for Intelligent Systems in Stuttgart, in a news release.

The Harbin Institute of Technology in Shenzhen, China helped make the materials and the reaction partners fully-biocompatible.

“Previous chemical drives of this kind were usually based on a metallic catalyst at the surface of which hydrogen peroxide was broken down into hydrogen and oxygen molecules,” said Sanchez, who also holds a professorship at the Institute for Bioengineering of Catalonia in Barcelona.

The use of hydrogen peroxide and gas bubbles in the human body is not ideal. The urease-coated nanotubes are water-soluble and bubble-free, making it safe for use in the human body.

Researchers on this study intend to test the biocompatibility of the method and plan to see whether microtubes can be implanted into individual cells to transport drug molecules to desired locations.

The research was published online in the Journal of the American Chemical Society.

[Want to stay more on top of MDO content? Subscribe to our weekly e-newsletter.]