Imagine being able to print out any device you would need in order to get a proper diagnosis.

Researchers from the product design and development department at Cambridge Consultants, a UK-based company that develops medical products, created the technology to make it happen. Using inkjet printing technology, the device is developed with a piece of paper, ink, and a printer.

“The XylemDx technology turns a sheet of paper into any one of a variety of different diagnostic tests, each of which can be produced on the same fabrication device,” says the Cambridge Consultants website.

The resulting device detects for diseases using blood, mucus, urine, or saliva samples.

To create the device, two printing processes occur: wax printing and printing commercially available ink on top, according to Nick Rollings, principal engineer at the Cambridge Consultants medical technology division.

The wax printing is used to create the fluidic pathways. This is accomplished using a conventional Xerox wax printer.

The wax is printed directly on chromatography paper.

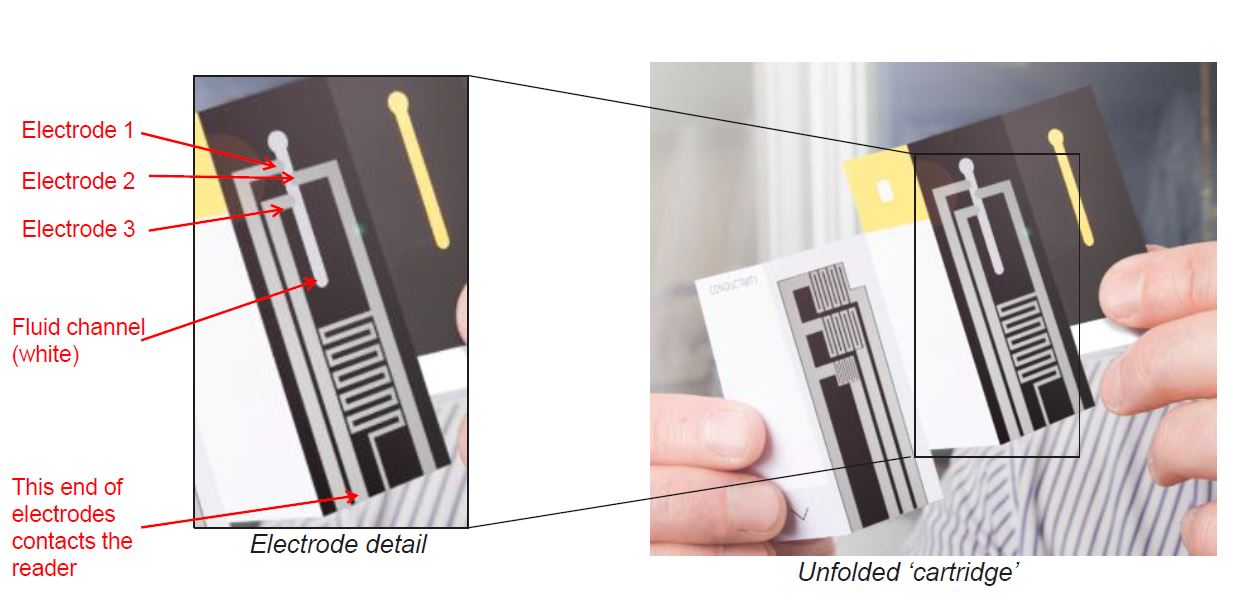

(Credit: Cambridge Consultants)

“We then heat this up so the wax flows into the chromatography paper and manages the flow of the liquid within the paper once it is dispensed,” explains Rollings.

Next, commercially available ink that consists of silver (the conductive material) and Ethanol (the carrier) is printed out right on top. The Ethanol evaporates, leaving the silver behind.

The device also includes a sensor that is created by printing electrodes in different patterns within the wax fluidic pathway. This would allow the sensor to read the voltages, giving the sensor the ability to tell the difference between salt water and fresh water.

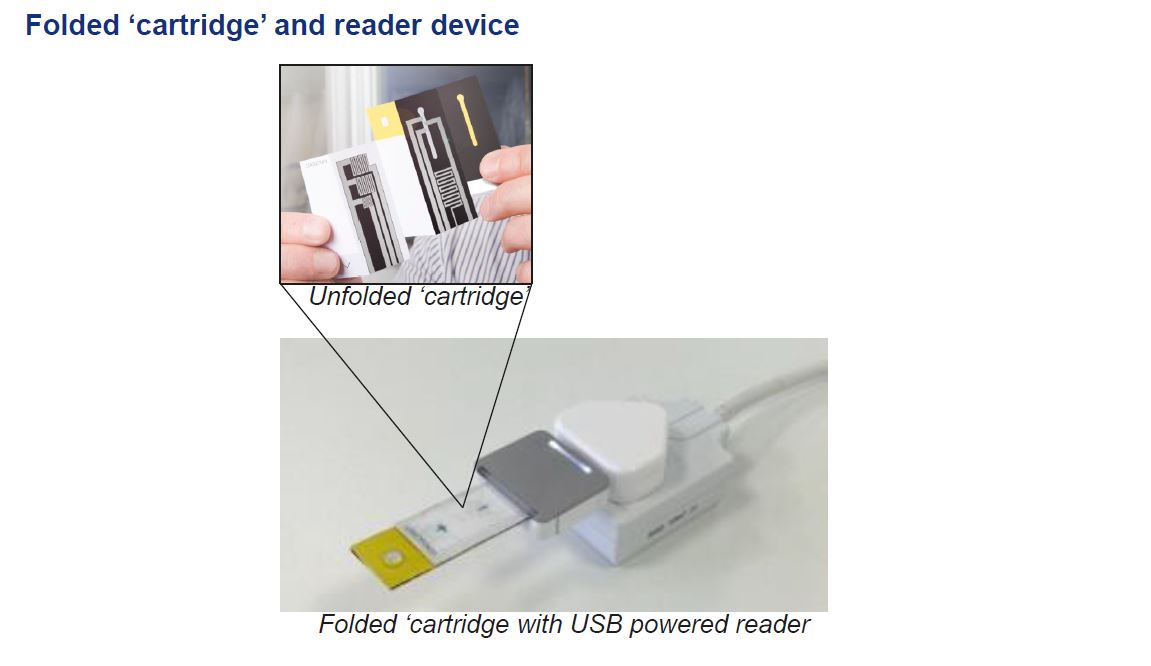

Specifically, electrode one and electrode three share electrode two in order to create two pairs of electrodes. Using a pipette, the user dispenses a sample (blood, urine, saliva) into the fluid channel, and the sample flows through. The user then inserts the folded cartridge into a USB-powered reader.

Once inserted, “the reader will send a voltage through electrode one,” says Rollings.

“If there is fluid in the channel, this makes up the circuit and allows voltage to flow into electrode two. If the reader sees a voltage at electrode two, then it confirms the presence of correctly inserted fluid (referred to as a ‘control’). The reader then sends a very specific voltage to electrode two. The sample in the fluidic channel allows the circuit to be made and the voltage to flow into electrode three. The reader then measures the voltage that has come back via electrode two. If the voltage is ‘high’ (i.e. pretty much the same as originally supplied to electrode two), then it indicates a sample with high conductivity (e.g. saline solution). If the voltage measures at electrode three is ‘low’, then it indicated a sample with a lower conductivity (e.g. deionized water). This way, it is possible to quantify the signal from each sample and tell the difference between saline solution and deionized water.”

(Credit: Cambridge Consultants)

This relates to diagnostics because the method used to detect the difference between saline solution and deionized water, called “electrochemistry,” is almost the same as the method used in several diagnostic tests.

“Electrochemistry involves passing a known voltage and then taking a reading,” explains Rollings. “If the reading is above a ‘threshold’ value (established beforehand), then the substance in question (in this case, salt), is present.”

Similarly, a reading below the “threshold” means the substance is not present.

The cartridge is designed as a “tri-fold,” due to the number of features the cartridge needs. Each cartridge needs to have the same final profile, so more features result in more folds.

Rollings had the idea for this project after co-writing an article on semiconductors based on diagnostic technologies. He realized that the technologies could create a variety of diagnostic tests.

“As these electronics fabrication techniques were already being applied in diagnostics, we looked into the latest generation of ‘digital’ fabrication techniques and instigated an internal project to explore this, further resulting in the XylemDX concept,” he says.

“Each piece of paper can be configured with a bespoke set of test modules – for example, electronic, thermal, fluidic, optical, or biological reagent modules – before being folded concertina-style into the traditional test cartridge shape. For diagnostic manufacturers, this opens up the possibility of low-cost prototyping and development, as well as a universal production methodology.”