Control-Flex® couplings from Zero-Max are designed for the precision feedback requirements of encoder applications.

Featuring a unique Control-Flex center disc design, these couplings have a parallel linkage system that minimizes reaction forces due to unavoidable shaft misalignments.

Control Flex couplings have high parallel, angular and axial shaft misalignment capabilities with considerably less side loads on shaft bearings and seals. They are designed with clamp-style zero backlash hubs, and have electrically insulating flex components with low weight and inertia.

When compared to standard beam style couplings, Control Flex couplings have the added features of clamp hubs and electrical insulation. Control Flex couplings were intentionally designed to be used for encoders.

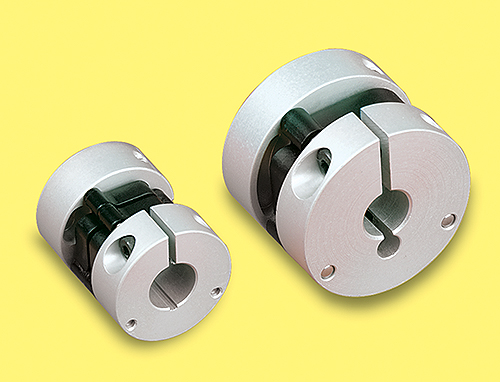

Precision designed, Control-Flex couplings consist of two hubs (to be attached to the system shafts) and a center flex member. This flexible member is affixed to the hubs through pins. Clamp style hubs provide a positive shaft connection. Two versions of the coupling are available: single flex disc version for standard torque capacity, and two flex disc version for increased torque capacity and torsional stiffness.

Control Flex couplings are ideal for use in packaging, medical device, machine tool, conveying and automated assembly systems – wherever encoders are used.

Control-Flex couplings are now available with configurable 3D CAD downloads at: www.zero-max.com/3D

Zero-Max

www.zero-max.com

::Design World::