NEWS RELEASE: Covestro polycarbonate utilized for a breakthrough wound healing device, an innovative airway monitoring device, and for durable mobile device protection in healthcare settings

Potential to transform wound healing: Covestro medical-grade Makrolon® polycarbonate utilized for breakthrough wound healing device

- Vaporox’s Vaporous Hyperoxia Therapy (VHT®) technology is clinically validated for healing skin wounds

- A combination of Covestro resin and technical support helps bring next-generation wound care medical device to market

Vaporox’s VHT-200 (Vaporous Hyperoxia Therapy™) system features a unique combination of elements—ultrasonic vapor and concentrated oxygen—shown to accelerate the healing of chronic wounds. The vaporizer assembly of the medical device primarily utilizes Makrolon® 2458 polycarbonate from Covestro. [Photo courtesy of Covestro]

The VHT-200 (Vaporous Hyperoxia Therapy™) system, which received U.S. Food and Drug Administration (FDA) clearance, features a unique combination of elements that accelerate healing—ultrasonic vapor and concentrated oxygen. According to Vaporox, the patented delivery system for these elements promotes revascularization and tissue growth. The treatment is intended for administration in clinics and physicians’ offices.

“Vaporox is committed to a world where all wounds heal,” said Chase Huskey,

marketing manager, Vaporox. “Today, wound care is one of the most under-served markets in the medical industry, but this development is truly life-changing for patients and a huge step forward for this market.”

Covestro was involved throughout the device’s development, supplying prototype quantities of its material, and documentation required by the FDA.

Makrolon® 2458 polycarbonate is a low-viscosity, injection-molding medical grade that features easy release from the mold. It is suitable for Ethylene Oxide (EtO) and steam sterilization and is biocompatible according to many ISO 10993-1 test requirements. It is available in transparent and opaque options.

“For decades, the healthcare market has relied on our proven portfolio of medical grade Makrolon® polycarbonates, complemented by customized technical expertise,” said Mark Nichols, healthcare key account manager, Covestro LLC. “Our work with Vaporox demonstrates the value of collaboration as our customers develop and bring truly innovative, game-changing technology to market.

Attendees at MD&M West, February 6-8 in Anaheim, California, can visit the Covestro booth (#2221) to learn how the company’s materials are pushing boundaries in healthcare applications.

Clearing the air: Covestro polycarbonate selected for innovative airway monitoring device

- VentRight Monitor from Certus Critical Care aims to empower healthcare providers to manage patient-ventilator asynchrony

- Makrolon® polycarbonate selected for biocompatibility and impact strength needed for this demanding application

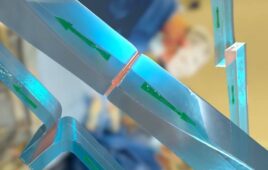

Covestro is supplying Certus Critical Care with its Makrolon® 2458 polycarbonate, used in the water trap and airway chamber. [Photo courtesy of Covestro]

Certus Critical Care is developing the VentRight Monitor (VRM), an airway monitoring medical device, to improve patient care in critical situations requiring mechanical ventilation. The VRM uses multiple sensors and advanced algorithms to accurately identify multiple types of PVA along with clinical decision support to assist providers in effectively managing these PVAs. By offering precise detection and monitoring, the VRM aims to empower healthcare providers in emergency departments, intensive care units and medical transport with the information needed to optimize patient care in real-time. For this innovative technology, Covestro is supplying Certus Critical Care with its Makrolon® 2458 polycarbonate, used in the water trap and airway chamber. Makrolon® 2458 offers biocompatibility and impact strength with the appearance of glass, which is necessary in critical care environments. Certus Critical Care also has plans for a supporting monitor, which will use Covestro material for its housing.

Makrolon® 2458 polycarbonate is a medical grade thermoplastic material that meets ISO 10993-1 and USP class VI. Available in transparent and translucent colors, this material offers biocompatibility and impact strength with the appearance of glass. Bayblend® M850 XF PC+ABS, a medical grade thermoplastic material, offers rugged durability and high chemical resistance for challenging medical environments.

“The VentRight Monitor is a technological advance that will help answer an unmet need in the healthcare market,” said Mark Nichols, Healthcare Key Account Manager, Covestro LLC. “We are working closely with Certus Critical Care to provide a high-quality, proven material that meets the rigorous requirements of this potentially life-saving product.”

Covestro was selected as a partner because of its reputation for producing high-quality, durable engineering plastics, according to Certus Critical Care. ”Their materials not only met but exceeded our needs for durability, resistance to sterilization processes, and compliance with biomedical standards,” said Jared Spendlove, Director of Operations and Manufacturing, Certus Critical Care.

“Utilizing Covestro’s materials allowed us to design a product capable of withstanding the demanding conditions of critical care environments, providing a reliable tool for healthcare professionals, and setting a new standard in patient-ventilator monitoring.”

Make the case: Covestro polycarbonate for durable mobile device protection in healthcare settings

- Beam Mobile solutions designed for device protection in healthcare settings

- Makrolon® polycarbonate is a solution that withstands hospital environments

Beam offers impact-resistant polycarbonate case for iPhone and iPad deployments. [Photo courtesy of Covestro]

Beam Mobile offers durable cases designed specifically for the healthcare industry made with Covestro’s Makrolon® polycarbonate, a high-performance material known for its chemical and impact resistance and durability. Beam Mobile offers the only case on the market utilizing plastic that can hold up against hospital-grade cleaners and disinfectants. Additionally, Beam Mobile cases come with a swappable battery to extend battery life for long shifts without the need to take the device out of the case.

“We collaborated throughout the resin selection process to ensure that Makrolon® polycarbonate satisfied the rigorous impact and cleaning resistance required for daily use within the hospital environment,” said David Bowker, Director of Engineering, Beam Mobile. “As a result, Beam Mobile cases are trusted by major hospitals worldwide and provide maximum protection—even withstanding frequent drops and rough handling.”

Makrolon® polycarbonate is exceptionally robust, lightweight and features a range of grades to meet the chemical and disinfectant resistance needs of many medical applications. It is noted above all for its toughness, heat resistance and dimensional stability. It offers the design freedom needed for Beam Mobile’s ergonomic design and suite of products.

“Our Makrolon® polycarbonate is the perfect material for this application, offering excellent impact resistance, and biocompatibility,” said Zachary Williams, Market Development, Covestro LLC. “We are committed to working with innovative companies like Beam Mobile to develop solutions that meet the unique needs of the healthcare industry.”

About Covestro

Covestro is one of the world’s leading manufacturers of high-quality polymer materials and their components. With its innovative products, processes and methods, the company helps enhance sustainability and the quality of life in many areas. Covestro supplies customers around the world in key industries such as mobility, building and living, as well as the electrical and electronics sector. In addition, polymers from Covestro are also used in sectors such as sports and leisure, cosmetics and health, as well as in the chemical industry itself.

The company is committed to becoming fully circular and is striving to become climate neutral by 2035 (scope 1 and 2). Covestro generated sales of EUR 18 billion in fiscal 2022. At the end of 2022, the company had 50 production sites worldwide and employed approximately 18,000 people (calculated as full-time equivalents).

Find more information at www.covestro.us.

Read our Corporate Blog.

The opinions expressed in this news release are the author’s only and do not necessarily reflect those of Medical Design & Outsourcing or its employees.