By Eduard Dobre, Senior Program Manager

When it comes to medical devices, time to market is critical, not only is it a competitive advantage, but it can sooner help patients in need. While the process can be lengthy, from proof of concept all the way to commercialization, laser processing capabilities can shorten the development stage.

When it comes to medical devices, time to market is critical, not only is it a competitive advantage, but it can sooner help patients in need. While the process can be lengthy, from proof of concept all the way to commercialization, laser processing capabilities can shorten the development stage.

Weiss-Aug Group’s Laser Lab Technology Center – shown below, part of Weiss-Aug’s Surgical Products division, is located in Fairfield, NJ. It’s array of laser processing technologies expand on Weiss-Aug’s existing capabilities to better support the demanding developmental requirements of today’s fast moving medical device market.

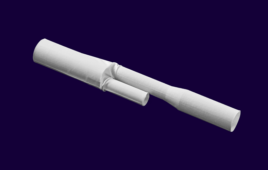

Precision laser cutting is faster, requires shorter setup, can process a vast array of raw materials and material tempers compared to that of traditional CNC technologies, all without sacrificing precision. This leads to quicker turnaround times for prototyping, putting parts in the hands of customers in hours, not days or weeks.

Our equipment includes a new modulated fiber laser system. This latest generation technology enables laser cutting of materials with thicknesses to 1.5 mm (0.059 in) and delivers high-performance cut accuracy to ±25 µm (±0.001 in). High quality optical components allow precise 2D and 3D engraving, as well as marking.

The combination of this technology with Weiss-Aug Group’s 3D optical, laser and touch probe measurement systems allow fast deviation analysis and the creation of digital models for instant feedback to the iterative process. Customers benefit from this by being able to quickly test and modify prototypes to develop the best design.

The combination of this technology with Weiss-Aug Group’s 3D optical, laser and touch probe measurement systems allow fast deviation analysis and the creation of digital models for instant feedback to the iterative process. Customers benefit from this by being able to quickly test and modify prototypes to develop the best design.

Weiss-Aug Group’s foundation in high volume precision metal stamping and insert-molding ensure that prototypes emulate the manufacturing process which result in designs that are cost effective and repeatable.

“At the end of the day, customers need to quickly iterate designs to feedback into final products and be assured that those part designs are manufacturable” says Michael Cullen, VP of engineering at Weiss-Aug Surgical Products. “With Weiss-Aug’s 50+ years of experience and expertise in tooling, metal stamping and molding now combined with the latest prototype technologies, we can provide our customers with superior prototypes and superior manufacturing solutions”

“At the end of the day, customers need to quickly iterate designs to feedback into final products and be assured that those part designs are manufacturable” says Michael Cullen, VP of engineering at Weiss-Aug Surgical Products. “With Weiss-Aug’s 50+ years of experience and expertise in tooling, metal stamping and molding now combined with the latest prototype technologies, we can provide our customers with superior prototypes and superior manufacturing solutions”

The Surgical Products division of Weiss-Aug Group is focused on the development and manufacture of device components and assemblies utilized in surgical instrumentation. With facilities in the US and Mexico, Weiss-Aug Group provides complete production lines for medical device assemblies.

Learn more at www.weiss-aug.com/laser-processing/

Sponsored content by Weiss-Aug