Achieve unprecedented part reproducibility for peripheral, structural, neurovascular and cardiovascular innovations with high-precision laser processing.

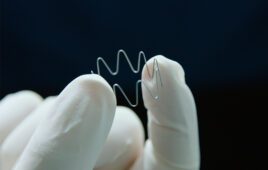

Precision laser cutting of a cardiovascular implant [Photo courtesy of Aerotech]

Vascular interventional devices are a modern marvel, helping to combat some of the most challenging medical conditions. Strokes, blocked arteries and failed heart valves are no longer death sentences, thanks in no small part to these products.

To deliver broad access to these mission-critical devices without sacrificing quality, special attention must be paid to their manufacturing processes. Manufacturers started using lasers to cut these parts as early as the 1990s. As laser processing advanced — cutting, welding, ablation, drilling, marking — so did those manufacturing processes.

Here are some of the primary reasons why laser technology has become widely accepted as the standard for producing such intricate devices.

1. Unmatched precision when cutting or joining

Medical devices are becoming increasingly more complex. Often this complexity requires smaller features or more tightly controlled manufacturing processes to ensure process stability and product performance. Whether cutting or joining materials, lasers provide the tightest control over the processing of a given material. Properly designed laser cutting systems can deliver a single-digit micron kerf (cut width) with similar or better spot size placement accuracy. The same laser that delivers this manufacturing precision can just as easily remove atoms of material or cut through the entire thickness in a single pass with zero contact and zero wear, enabling the finest features to be cut into the thinnest and most exotic materials. As a result, laser processing enables vascular device manufacturers to create new and innovative products.

2. Enhanced process control and reproducibility

When properly specified and integrated with automated machines, lasers offer medical device manufacturers the highest levels of production control across manufacturing lots. Lasers are stable, proven, digitally controlled systems that allow device manufacturers to trace the parameters applied at the individual part serial number. This manufacturing process data can then be logged for historical analysis of quality metrics (e.g. gage repeatability and reproducibility or process capability indices). In addition, lasers and the digital motion controls used to trigger and position them can be calibrated with advanced sensors as often as necessary to minimize part-to-part, lot-to-lot and even machine-to-machine variation to near zero.

The image below shows an example of a laser-cutting machine with a view of the mechanics and control software used for making medical devices.

This photo montage of an automated tube cutting machine includes an Aerotech LaserTurn5 (upper left) positioning nitinol tubing relative to a laser head, Aerotech’s Automation1 control interface (upper right) enables digital tracking of numerous motion attributes to control manufacturing processes, a visualization of Aerotech’s CADFusion (lower left), which allows design engineers to convert DWG, DXF or Bitmap files directly into machine G-Code, and A laser tube-cutting machine (lower right) as seen through laser-safe glass. [Image courtesy of Aerotech]

3. Minimized heat-affect zones (HAZ)

Several materials used in manufacturing the aforementioned medical devices are thermally sensitive. Imparting too much heat to a given process may result in adverse changes to material properties that are key to device performance. Nitinol, a common material in this class of products, is used for its unique combination of shape memory, elasticity and ductility. These properties are only maintained if nitinol is not exposed to excessive heat, a common side effect of mechanical processes. Recent advances in laser and automation technologies enable controlling beam pulses into the femtosecond (10-15) time domain. With the advent of this ultrafast laser technology, thermally sensitive materials like nitinol, foils, polymers and adhesives can be processed using ablative techniques with a minimal HAZ.

4. Improved throughput

Compared to traditional mechanical machining processes, laser processing also offers improved speed. Managing the challenges associated with traditional machine techniques often negatively affects throughput. With short-pulse lasers and machine controls that are tightly coupled to the laser, an advanced motion control system can deliver laser energy to the part at the desired position regardless of the cutting speed and/or change in cutting speed. This enables the motion path to be optimized for higher speeds and accelerations resulting in a significant throughput advantage.

5. Minimized post-processing

Laser processing generates significantly less debris than traditional machining methods, making this form of machining cleaner. While many laser cutting processes will still generate waste or dross, larger pieces of material are easily cleared from the process with assist gas or vacuum collection systems, unlike the fine chips or dust created by a mechanical method. Chemical post-processing removes any small amounts of dross or surface changes due to the heat input from the laser. In addition, using ultra-fast lasers for laser ablation virtually eliminates HAZ and dross, minimizing post-processing. Traditional manufacturing processes might also require the use of flux, pigments and solvents. Laser machining stands out in this regard, as processes like cutting, welding, ablation, drilling and marking do not require chemicals, flux or pigments.

What’s the catch with laser processing?

Aerotech Product Manager Bryan Germann [Photo courtesy of Aerotech]

Learn more about lasers for device manufacturing in our Medical Design & Outsourcing webinar, Precision Automation Technologies that Minimize Laser Cut Hypotube Manufacturing Risk.

Aerotech Product Manager Bryan Germann focuses on light manipulation products, including Aerotech’s AGV laser scan heads and associated Automation1 drives and software control features. He has hands-on experience designing and managing the production of high-precision motion control and automation machinery and products. Germann earned his bachelor’s and master’s degrees in mechanical engineering from the University of South Carolina. He holds 17 U.S. and international patents.

Travis Schneider [Photo courtesy of Aerotech]

How to submit a contribution to MDO

The opinions expressed in this blog post are the author’s only and do not necessarily reflect those of Medical Design & Outsourcing or its employees.