No. 250, Sing Jhong Road

Tamsui, New Taipei City 251, Taiwan

Phone: 886(2)26228651

www.powerspring.com.tw

Ming Tai Industrial Company expects to be your best engineering consultant for steel strip spring application with enthusiasm. Recently Ming Tai has been helping lots of customers to develop medical devices which apply steel strip spring successfully. All innovative products include pen type drug injector, high adjustable monitor and keyboard integrated medical workstation, high adjustable trapeze for patient bed, and patient bedside table, Bowden cable for endoscope, draw wire encoder for MRT machine. Both performance of Ming Tai’s steel strip springs and manufacturing service are gain lots of praise and appreciation from customers.

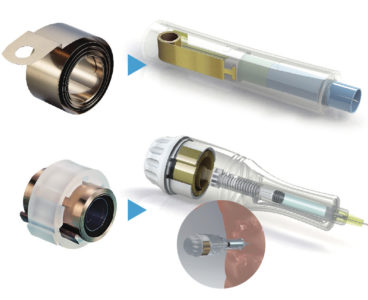

In Figure 1, it explains that variable force torque spring exerts constant force to keep injecting drug with fixed flow, to prevent patient from feeling uncomfortable. Variable force torque spring also features stretch force in the end the stroke that ensure pen type drug injector dose drug entirely

In Figures 3, you can find constant force spring features counterbalance. These can be applied to high adjustment application, such as patient bedside table.

Since there are a number of different spring design possibilities for a given application, you are welcome to contact us in the early design phase to create an optimized spring solution for your demand. Along with high quality production, prompt delivery and competitive pricing. Ming Tai is your best partner to win the market.

Total solution for steel strip spring application

Ming Tai Industrial Co., Ltd. is one of the leading manufacturers of steel strip springs for medical device applications, including; Constant Force Spring, Constant Torque Spring, Power Spring and Pre-stressed Power Spring, Variable Force Torque Spring, Variable Torque Spring and Spring-Strip Tube.

With ISO 9001: 2015 and RoHs certificated, Ming Tai is capable of serving customer from the technical support in develop procedure, prototype, to trial run, mass production, spring mounting and assembly. Each manufacturing procedure, including steel strip slitting, heat treatment, edge trimming, forming process is consistent production and completed in-house to ensure highest quality requirement.