1550 Utica Ave South Suite 555

Minneapolis, Minnesota 55416

https://www.trelleborg.com/en/healthcare

Trelleborg Expands its Offerings through Acquisition

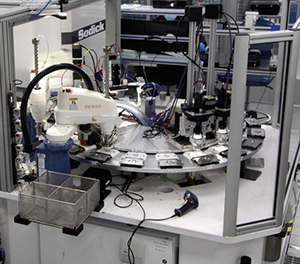

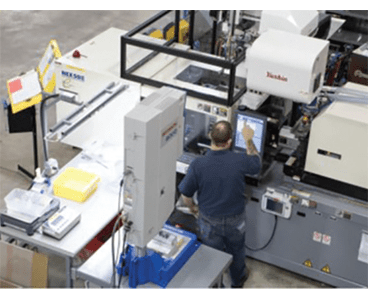

Trelleborg has expanded its capabilities and offerings to medical device customers with the recent EirMed and Minnesota Rubber & Plastics (MRP) acquisitions. These acquisitions enhance Trelleborg’s ability to partner with customers on projects involving thermoplastic and rubber injection molding, assembly, packaging, bioresorbables and more. The acquisitions further Trelleborg’s ambition to provide innovative, custom solutions to customers by accelerating product development and strengthening research and development.

Trelleborg can now leverage MRP’s established excellence in polymer and thermoplastic components and its strategically located manufacturing facilities that complement Trelleborg’s manufacturing network. MRP production facilities in the US, Mexico, Europe, and China enable Trelleborg to have a manufacturing presence close to medical device customers. Local manufacturing decisions can be made per component, depending on part complexity, labor content, supply chain risk level, demand, and more.

By the numbers

Accounting for its added reach with MRP, Trelleborg now has 10 research and development centers, 41 manufacturing facilities specializing in market-leading solutions, 61 Customer Solution Centers offering local engineering and support services, one Customer Innovation Center, five logistics centers, and three ServicePLUS Centers.

Your Partner for Life-Changing Technologies

Trelleborg Healthcare & Medical helps pharmaceutical and medical device companies improve patient quality of life by partnering in all stages of development, from concept to serial production to create engineered polymer solutions for demanding applications. Trelleborg’s global footprint is backed by experts with 30-plus years of industry experience and a portfolio of capabilities including silicone molding, extrusion, sheeting, dipping and coating, overmolding, plastic injection molding, multicomponent manufacturing, drug-eluting technologies, engineered coated fabrics and other technologies. Additionally, customers have access to a variety of materials, such as Liquid Silicone Rubber (LSR), thermoplastics, black rubber, bioresorbables and other polymers and elastomers.