Surgical robotics leader Intuitive Surgical and imaging juggernaut Philips are both licensing fiber optic technology for minimally invasive procedures through longstanding agreements with Luna Innovations Inc.

But for medical device developers who don’t have access to that fiber optic navigation technology, there’s another option: The Shape Sensing Co. (TSSC).

The Austin, Texas-based fiber optic startup is developing a shape-sensing endovascular guidewire and pursuing collaborations with other device manufacturers that are locked out of Luna’s intellectual property, TSSC CEO Ryan DeBoer said in an interview with Medical Design & Outsourcing.

DeBoer acknowledged that Luna’s head start on the technology means TSSC has some catching up to do, but he thinks they can close the gap.

“We’re a small, nimble startup, so we’re moving more quickly than they were able to. But from what we understand, our technology’s performance is further along than” Luna’s was when it was acquired.

Luna has been working with Intuitive in the medical robotic field since 2007 and uses the technology in its Ion endoluminal system for robotic bronchoscopy.

Philips, meanwhile, sublicensed Luna’s IP for the nonrobotic medical field from Hansen Medical in 2011. (Hansen Medical sold to Auris Surgical Robotics in 2016; Auris sold to Johnson & Johnson’s Ethicon unit for $3.4 billion in 2019.) Philips uses the technology for the Fiber Optic RealShape (FORS) technology in its LumiGuide 3D device guidance system.

As a medical device developer, TSSC is focused on its guidewire. But it also sells its R&D equipment to other medical device developers to help them find ways to integrate the technology into their own devices, and it already has one device developer as a strategic investor, though DeBoer asked that the company not be publicly identified.

How fiber optics enable device navigation

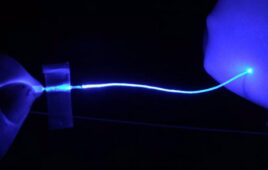

This demonstration from The Shape Sensing Co. shows how a fiber optic sensor can offer 3D visualization without fluoroscopy radiation or electromagnetic generators. [Images courtesy of The Shape Sensing Co.]

“We can use fiber optics to display the real-time shape and location of a guidewire in three dimensions,” DeBoer said. “We do this by transmitting light down the length of a fiber optic sensor, and then process reflected signals with complex algorithms to calculate the 3D shape.”

Strain measurements make the technology possible, Chief Technology Officer Alex Tongue said.

“As light travels down the optical fiber and is reflected back, we calculate strain associated with bending and twisting,” he said. “By summing these measurements along the length of the sensor, we can derive shape.”

Luna’s technology uses multicore fiber, which is a single glass fiber containing four cores within it. TSSC is using multiple, single-core fibers, Tongue said.

“Fiber is made using a draw tower, where a glass rod called a preform is heated and drawn into thin fiber,” he said. “Drawing fiber with multiple cores is far more complex than just a single-core, and therefore it is more costly. It’s also a simpler process to inscribe the reflective elements, or Bragg gratings, into single-core fiber than into multicore. The multicore fiber could be considered a more elegant solution since it’s all self-contained, whereas our multiple, single-core fibers are held together with an adhesive. However, the complexity of multicore fiber results in lower yields, reduced reliability, and higher costs.”

Tongue and DeBoer declined to describe the adhesive, citing proprietary reasons.

TSSC’s fiber has a diameter of only about 300 microns, but Luna’s tech was at one time somewhere around 200 microns. Size directly relates to bending radius, so the smaller the fiber, the smaller the bending radius, Tongue said.

“They can probably withstand slightly tighter bends today, but in the future, we are confident we can achieve down to just a few millimeters,” he said.

“In terms of accuracy, we don’t have a head-to-head test,” he continued, “but current testing indicates that our average shape accuracy along the full length of the sensor is sub-millimeter. With that level of accuracy, we’re confident that we can pursue any medical application.”

DeBoer said the manufacturing differences for single-core fiber versus multi-core fiber will lead to lower costs for TSSC’s products. That could allow TSSC to sell single-use disposables. Shape-sensing products sold by Intuitive and Philips are reusable.

TSSC’s first fiber optic guidewire

The Shape Sensing Co.’s first device is an endovascular guidewire. [Photo courtesy of The Shape Sensing Co.]

“Our beachhead application is going to be endovascular aneurysm repair, in particular the complex versions, which are FEVAR (fenestrated endovascular aortic repair) and ChEVAR (chimney endovascular aortic repair) with the goal of reducing radiation exposure during these very long procedures that vascular surgeons are are performing,” he said.

That first-generation device will be a minimally viable product for limited release to TSSC’s advisors to learn more about the procedures for full commercialization of a more refined version of the device in 2027. The company is raising a Series B funding round for the first two generations of the device.

“Our team is very focused on our FDA clearance,” DeBoer said. “We are pursuing a couple supplier relationships who will help us take this across the finish line for FDA. We’re already in in discussions with some of those.”

Those suppliers include a contract development and manufacturing organization (CDMO) with specialized capabilities for fiber optics.

“We’re going to be very, very picky in who we decide to go with for manufacturing,” he said.

Opportunities for other device developers

The Shape Sensing Co. CEO Ryan DeBoer [Photo courtesy of The Shape Sensing Co.]

Some of TSSC’s R&D equipment buyers are pursuing similar applications as Intuitive and Philips, DeBoer said. Others are exploring broader potential across robotics, cardiology, structural heart, electrophysiology and gastrointestinal applications.

TSSC also sees opportunity in orthopedics, neuro and anywhere else where a tool goes into the body is tracked with fluoroscopy, electromagnetic navigation or infrared light.

“We have gotten a lot of requests for an option to explore the neurovascular space,” DeBoer said. “The caveat to the brain, of course, is that the vessels are smaller. So we are working on a next-generation device that will be able to be small and flexible enough to go into the brain.”