Treasa Springett is president of Donatelle Plastics Inc. – a world-class contract manufacturer of medical components and devices, specializing in injection molding, LSR, precision machining, device assembly, and tool building. Springett joined Donatelle in 2004 and built an executive staff and Leadership Team that have continued to grow the business by developing and expanding processes, capabilities, and technologies, and offering these enhanced capabilities to our global Medical Device OEM customers. With over 55 years of experience, Donatelle manufactures products across many markets within this industry, including cardiac & vascular, neuromodulation, orthopedic, ophthalmic, diabetes & drug delivery, diagnostics, and surgical technology.

Treasa Springett is president of Donatelle Plastics Inc. – a world-class contract manufacturer of medical components and devices, specializing in injection molding, LSR, precision machining, device assembly, and tool building. Springett joined Donatelle in 2004 and built an executive staff and Leadership Team that have continued to grow the business by developing and expanding processes, capabilities, and technologies, and offering these enhanced capabilities to our global Medical Device OEM customers. With over 55 years of experience, Donatelle manufactures products across many markets within this industry, including cardiac & vascular, neuromodulation, orthopedic, ophthalmic, diabetes & drug delivery, diagnostics, and surgical technology.

Springett has more than 35 years of contract manufacturing industry experience in medical device product development and manufacturing; having served in many leadership roles spanning from engineering, sales, operations, and administrative functions. Prior to joining Donatelle, Springett was vice-president of manufacturing for a major contract manufacturer responsible for over 15 manufacturing sites and more than 2000 employees. A transformational business leader, Springett has led cultural change and technological advancements that have become foundational in achieving organizational success at all levels and across multiple disciplines. Springett contributed to numerous technical papers and industry handbooks to further advancement of technology related to injection molding. She served on several university boards, including the University of Wisconsin-Stout Plastics Engineering Program as an Advisory Board Member, and the Dunwoody College of Technology as a Board Trustee and on the Student Academics and Program Advisory Committee.

What initially attracted you to the medtech industry? How has your perspective on the industry evolved over the course of your career?

As I started my career as a mechanical engineer, I never really thought about the specific industry I would work in, rather my interest was more about the type of work, that being mechanical engineering and how it supported manufacturing. Early in my career, I worked as a manufacturing engineer for a custom contract manufacturer whose customers included many major medical device companies. Having an opportunity to design and build products and devices that touch people at a point of care and can improve the quality of life for them is very rewarding work. I have been pursuing this passion ever since that first engineering position and today 100% of the focus for the company I lead is on the medical industry.

As technologies advanced in manufacturing processes, automation, metrology, and other areas, contract manufacturers such as Donatelle partnered with medical device OEMs to design, develop, and manufacture devices that at one time were not possible to produce.

As a seasoned professional in the industry, how do you envision the future of medtech? What emerging technologies or trends do you believe will have the most significant impact?

Medtech has an exciting future offering devices and therapies that in the past would not have been possible. Wearable devices, Telemedicine, and Robotic surgical technologies along with use of AI in diagnostics will have a greater impact in Medtech’s future. COVID 19 accelerated telemedicine and this will expand to enable accessible and affordable healthcare. Advances in additive manufacturing that include plastics, metal, and tissues at microscale will further the medtech to the levels that were unimaginable in the recent past.

From your experience, what are some of the key challenges that medtech engineers are likely to face in the coming years? How can professionals in the industry prepare for and navigate these challenges effectively?

Some of the key challenges we face today and certainly will become even greater challenges are related to time and cost to develop new products and gain necessary regulatory approval to manufacture and market them. The known shortage of people resources across all areas from design to manufacturing is an ongoing challenge we all face. Applying technology and automation can certainly help alleviate these challenges within the manufacturing area. Collectively within the medtech space, medical device OEMs, along with supply chain partners, and regulatory bodies need to work together to streamline processes to reduce overall time and cost to deliver new and improved devices.

In your opinion, what areas or applications within medtech have the greatest potential for growth and innovation? Why do you consider them promising?

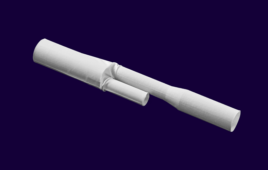

Applying Micro Manufacturing process capabilities in the design and development of new products has great potential for growth and innovation. Being able to manufacture micro components with extremely small feature sizes and geometries afford medical device companies the ability to develop new devices that often can deliver multiple therapies and enhanced patient benefits all within the same device. Although this is a significant advantage, particularly for implantable-type devices, Micro Manufacturing can be applied across many markets within this industry, including cardiac & vascular, neuromodulation, orthopedic, ophthalmic, diabetes & drug delivery, diagnostics, and surgical technology.

Another area that will have great potential for growth and innovation is how Additive Manufacturing Technology will augment the more traditional processes such as injection molding, precision machining, and others.

As technology continues to advance rapidly, how do you think medtech engineers can stay ahead of the curve and ensure they are equipped with the necessary skills and knowledge?

Engineers can stay ahead of the curve by researching and keeping abreast of innovations and technologies, attending industry tradeshows, seminars, and being actively involved with industry-specific professional organizations. They should explore and adapt to emerging technologies relevant to their field. These include Additive Manufacturing, data analytics, virtual reality and artificial intelligence along with machine learning. Another way is by collaborating within their own organizations and sharing lessons learned from current and past projects.

From a broader perspective, how do you see the role of medtech engineering in shaping the future of healthcare? What impact do you anticipate it will have on patient care and outcomes?

Engineers applying new technologies and process capabilities will enable innovation for the future of healthcare by being able to create geometries that are currently not possible to manufacture. Technologies such as Additive Manufacturing will enable shorter lead times for development and offer alternative manufacturing options depending on product and volume requirements. These types of technological advancements will greatly benefit patient care and outcomes by providing new therapy solutions with less invasive and involved procedures, shorter hospital stays, and in some cases therapy solutions that today may not exist.

Considering the increasing importance of interdisciplinary collaboration, how do you think medtech engineers can effectively collaborate with professionals from other fields, such as medicine and computer science, to drive innovation in the industry?

Collaborating with medical professionals, medtech engineers can enhance their effectiveness by gaining valuable clinical insights, incorporating patient-centered designs, validating products through clinical trials, navigating products through regulatory compliance, and staying up to date on medical advancements. Furthermore, by working alongside computer science professionals, they can develop algorithms, ensure secure data management, create user-friendly software interfaces, prioritize cybersecurity, implement health informatics solutions, and integrate machine learning and AI capabilities. This interdisciplinary collaboration fosters the development of innovative, practical, and secure healthcare solutions. In this rapidly evolving field, continuous learning and communication are crucial for successful partnerships.

How do you think diversity and inclusion can contribute to the advancement of medtech engineering? How do you foster a culture of innovation within your team or organization?

Diversity and inclusion play a crucial role in the furthering of medtech engineering. When a diverse group of individuals collaborates, they bring unique perspectives to the table. This diversity of thought allows for more comprehensive problem-solving and the exploration of a wider range of potential solutions. In medtech engineering, this can lead to the development of more effective and inclusive technologies that cater to diverse patient populations. Inclusive teams encourage a culture of creativity and innovation. When people from different backgrounds come together, they can combine their individual talents and expertise to generate new ideas and approaches. This can result in the creation of innovative medical devices that address unmet needs.

We foster a culture of innovation by embracing open communication, promoting collaboration, supporting calculated risk-taking and providing learning opportunities. In addition to the above, celebrating innovative thinking and rewarding the individuals who contribute to the advancement of the organization’s goals will reinforce the innovation culture.