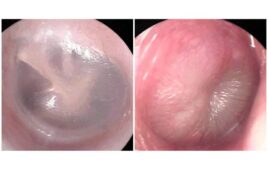

The Swab56 Project’s FiberFlex swab, produced with help from Goddard. (Image from Swab56)

Mechanical engineering and industrial design company Goddard announced that it is working with the Swab56 Project to rapidly increase the production of Swab56’s test swabs, which are used in healthcare facilities to test for COVID-19.

As news reports have documented, traditional nasopharyngeal swabs are in short supply as healthcare facilities around the world struggle to keep up with the coronavirus pandemic. In the U.S., there is only one manufacturer of these desperately-needed swabs.

The Swab56 Project is a collaborative effort between the teams at Neurophotometrics and the San Diego COVID-19 Research Enterprise Network. Swab56’s Fiberflex swabs have a nylon shaft reinforced with carbon fiber. They are flexible, but can withstand mechanical force or torsion without break or shear.

The swab designs were evaluated for clinical use and passed rigorous mechanical performance tensile and torsional testing, according to the organization. The Swab56 team aims to eventually produce 1 million swabs from Neurophotometrics’ manufacturing facility in San Diego.

“We know that it will take inspired innovation to meet the demands of these unprecedented circumstances,” said Goddard CEO Andrew Goddard in a news release. “The Swab56 team has devised a highly effective and sensitive alternative to the traditional nasopharyngeal swab. We are delighted to join with them in this collective effort to help augment the testing supply chain in the fight against COVID-19,” said

“In the past six weeks, we’ve gone from having an idea to developing prototypes, conducting clinical testing and finally ramping up production,” added Swab56’s CEO Sage Aronson. “It has been a wartime effort and I could not be prouder of my team for stepping up to the plate. The team at Goddard has been working non-stop and it has been a pleasure to work with them.”