Jeff Hrivnak/Global Business Development Manager – Healthcare/Solvay

Engineering polymers have helped make healthcare simpler, safer and more cost-effective for decades, and together they helped to drive a global market that was valued at $9.69 billion in 2013, according to analyst firm Grand View Research. Further, Grand View projects that the versatility of medical polymers will fuel robust growth through 2020 to reach a market value of just more than $17 billion.

Specialty polymers – a category of materials defined by markedly higher performance than conventional resins – will only help to fuel the growth of the overall medical plastics market. This especially applies to applications in which replacing metal with a polymer could potentially lower a part’s overall cost, reduce its weight or enable a more ergonomic design.

Encompassing polysulfone (PSU), polyphenylsulfone (PPSU), polyaryletherketone (PAEK), polyetheretherketone (PEEK), polyarylamide (PARA) and other advanced polymers, this class of materials collectively offers better mechanical performance than engineering resins, as well as broader chemical resistance, higher thermal properties and often inherent flame retardance without the need for additives. These materials are also compatible with a broad range of sterilization technologies, such as steam, ethylene oxide, vaporized hydrogen peroxide and high-energy gamma radiation.

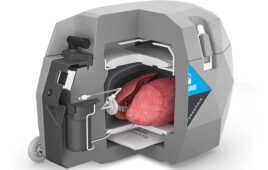

As with all healthcare thermoplastics, specialty polymers offer all the benefits that injection molding provides over metal fabrication, such as the ability to consolidate parts, cost-effectively mold complex components and eliminate secondary operations. Moldable polymers can also minimize the number of surfaces that need to be sterilized. Representative applications of complex or hybrid instrumentation in which injection-molded specialty polymers are playing a role include endoscopes and minimally invasive surgical instruments.

Yet specialty polymers offer more than the traditional processing benefits of conventional plastics. Their uniquely high-performance properties put them on par with many metals and often position them as a viable alternative. Metal has traditionally been the medical industry’s material of choice for components that require high rigidity and durability against heat, chemicals and sterilization. But specialty polymers are challenging metal on all of these points, while offering a more cost-effective, moldable alternative.

This is evident in the trend toward metal-replacement in single-use and reusable instrument applications, such as retractors, impactors and other surgical instruments. PARA’s metal-like strength and comparatively low cost vs. metal has further helped pioneer lighter, more ergonomic pliers, rod benders, staplers and other instruments traditionally reliant on stainless steel.

The greater compatibility of PSU, PPSU, PAEK, PEEK and PARA with chemical, steam and gamma-based sterilization methods is also helping to drive broader adoption. Reusable medical devices and surgical tools, for example, must undergo hundreds of steam sterilization cycles within their service lives, which exceeds the performance capabilities of commodity polymers and engineering plastics.

Single-use instruments are typically designed for sterilization with a gamma radiation dosage between 40 and 100 kGy. But despite their single-use label and counter to their instructions for use, these instruments have the ability to undergo several uses and sterilization cycles before they are discarded. The potential challenges are not lost on OEMs, who are seeking ways to design single-use instruments that are robust enough to retain critical properties if they are properly sterilized with gamma radiation, but visibly change in appearance if incorrectly sterilized using steam. Only specialty polymers combine the necessary mechanical properties, sterilization compatibility and colorability to achieve this goal.

The performance and versatility of specialty polymers will continue drive new applications and growth in the healthcare industry. Expect to see a growing number of examples in which these advanced materials expand design freedom through their stronger mechanical and physical properties, improved chemical- and heat-resistance and their compatibility with a broad range of sterilization techniques. Expect also to see them adopted in more and more applications that once relied on metal. In short, look forward to seeing specialty polymers open up entirely new and unexpected pathways to future growth in the medical polymers market.