Now with a new technology, LPKF is targeting the challenging medical applications market, and it is focusing on researchers and developers with demanding specifications for the joining technology.

Thanks to the reliability of the welding results, laser plastic welding has become established as the technical standard for mass production. Now with a new technology, LPKF is targeting the challenging medical applications market, and it is focusing on researchers and developers with demanding specifications for the joining technology.

Complex systems with channel cross-sections in the micrometer range are used for fast analysis in a number of fields, including food safety, clinical diagnosis, chemical synthesis and biological research.

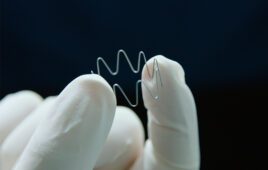

The high-precision mechanical and optical positioning system in the LPKF PrecisionWeld uses the welding properties of transparent plastics at a laser wavelength of 2 micron. This creates an effective technology for the prototyping and series production of microfluidic components.

The TechPaper describes the technical principles, the design implementation as a laser welding system, and the resulting welding parameters that can be achieved. The TechPaper can be downloaded at no cost on the LPKF website in the Knowledge Center.

LPKF

lpkf.com