3D printers are used to manufacture a variety of medical devices, including those with complex geometry or features that match a patient’s unique anatomy.

Some devices are printed from a standard design to make multiple identical copies of the same device. Other devices, called patient-matched or patient-specific devices, are created from a specific patient’s imaging data.

Commercially available 3D printed medical devices include:

- Instrumentation (e.g., guides to assist with proper surgical placement of a device),

- Implants (e.g., cranial plates or hip joints), and

- External prostheses (e.g., hands).

Scientists are researching how to use the 3D printing process to manufacture living organs such as a heart or liver, but this research is in early stages of development.

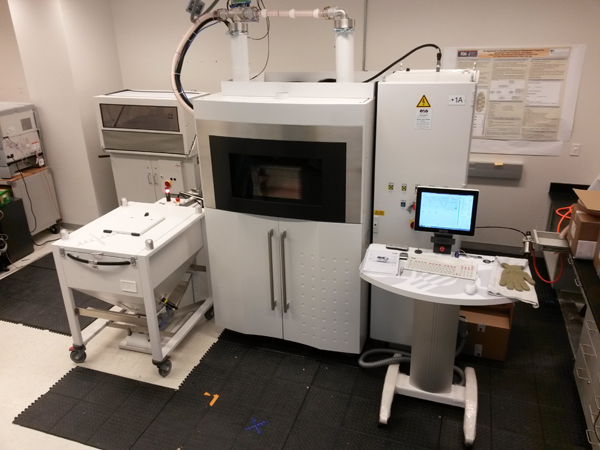

The 3D printing process can be accomplished using any of several different technologies. The choice of technology can depend on many factors including how the final product will be used and how easy the printer is to use. The most common technology used for 3D printing medical devices is called powder bed fusion. Powder bed fusion is commonly used because it works with a variety of materials used in medical devices, such as titanium and nylon.

FDA Powder Bed Fusion Printer (Credit: FDA)

The powder bed fusion process builds a three-dimensional product from very fine metal or plastic powder, which is poured onto a platform and leveled carefully. A laser or electron beam then moves across the powder layer and melts the material it touches. Melted material fuses to the layer below it and to the powder around it to create a solid. Once a layer is completed, the platform moves down and one more layer of carefully leveled powder is placed on top.

The FDA has several 3D printers that help us better understand the capabilities of 3D printing of medical devices and the public health benefit of this technology. For example, the FDA has printers that use different printing technologies, including powder bed fusion, to evaluate what parts of the printing processes and workflows are critical to ensure quality of the finished medical device.

Patient-matched devices

While 3D printers are often used to create identical copies of the same device, they can also be used to create devices unique to a specific patient. Patient-matched (or patient-specific) devices are created specifically for the patient based on individual features, such as anatomy. They can be based on a template model that is matched to a patient using medical imaging. Patient-matching can be accomplished by techniques such as scaling of the device using one or more anatomic features from patient data.

The FDA regulates 3D printed medical devices through the same pathways as traditional medical devices; therefore they are evaluated according to the safety and effectiveness information submitted to us by the manufacturer. While traditionally manufactured medical devices come in discrete sizes, patient-matched devices can be made in a continuous range of shapes with pre-defined minimum and maximum specifications that we can use to review the devices in the same way as standard sized devices. For instance, the specification may define a minimum and maximum wall thickness or how sharp a curve can be to maintain device performance for its intended use.

There is a provision in federal law that exempts “custom” medical devices from FDA review, but patient-matched devices do not automatically meet all the requirements. For further information on custom device exemptions, please refer to the Custom Device Exemptions guidance.

Other uses of 3D printing

The use of 3D printing is not limited to medical devices. Other industries and government departments are also interested in its use. For instance, the U.S. Department of Energy (DOE) is investing resources to study 3D printing, and how it can be used to reduce waste by using fewer raw materials and require fewer manufacturing steps. DOE has compiled information on how 3D printing works, the different types of printers and for what they are used. For more information on how 3D printers work and the different printing technologies, visit the DOE’s How 3D Printers Work webpage.