[Photo via Adobe Stock]

Plastics for surgical robotics and their accessories need certain properties for sterilization, heat resistance, performance and even aesthetics.

By Josh Blackmore, M. Holland

Surgical robotics systems improve patient outcomes and increase consistency of care, but building them isn’t always straightforward. Surgical robotics machines are a sizable investment and require the use of high-quality materials that perform the needed task, endure heavy usage and withstand stringent disinfection methods.

The FDA approves robotics systems to perform specific surgical procedures. Similar organizations throughout the world ensure standards for patient care. That means materials must meet different requirements set by regulatory bodies and individual medical care facilities while maintaining usability for surgeons of varying heights, sizes and skill levels. Each part of each machine is evaluated first for safety and efficacy with considerations for sterilization method, heat resistance and sustainability.

Withstanding sterilization

A sterile surgical environment is required to minimize infection and help ensure positive patient outcomes. Medical care facilities must constantly disinfect their tools and machinery to ensure patient safety. However, the harsh chemicals and methods used can damage equipment over time. The method of sterilization used will often determine which material is appropriate for each part of the machine.

Hard-surface disinfectants can range from alcohol to glutaraldehyde. Each hospital and region sets specific protocols, so materials must be able to resist a wide range of chemical sterilization agents. Materials that hold up to hard surface sanitization, like polycarbonate blended with polybutylene terephthalate, resist the effects of repeated chemical sterilization.

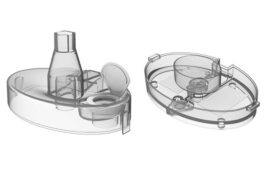

Gamma radiation is often used to disinfect single-use accessories for robotic surgery. When using radiation to sterilize, considerations must be made to maintain the accessory’s strength, color and performance. The material acetal, for example, likely will become brittle and can disintegrate when exposed to gamma radiation. Polycarbonate can turn yellow unless stabilized or colored, but won’t lose other important physical properties. Other materials might demonstrate no effect at all.

Improving safety while beating the heat

While disinfection is one critical consideration when selecting materials, some parts must meet multiple requirements. For example, housing for robots should be able to resist hard-surface sterilization and be flame retardant as electricity passes through the material during use.

And heat resistance is necessary for many reusable parts of surgical robotics machines to enable autoclave sterilization. Most resins can withstand one cycle of autoclave, but reusable parts must maintain performance through thousands of cycles. Polyphenylsulfone is one of the most heat-stable resins that can withstand repeated autoclave cycles. Polyphenylsulfone’s V=0 flame retardant capabilities ensure machines using electricity are safe to operate. Parts made from it will not ignite or melt, which is critical in an oxygen-rich environment like the surgical theatre.

Detachable parts such as foot pedals and hand controls made from heat-resistant materials can be removed, sterilized via autoclave, cleaned and reattached for subsequent surgeries. Electrocautery tools used by the robot must likewise be made of heat-resistant plastics to ensure the device can perform its intended function without igniting or melting.

Safeguarding against accidents

Surgical robotics machines often provide better patient care and outcomes than manual surgery. Meeting that promise from a materials standpoint means ensuring that elements of the device can precisely carry out their intended function. Single-use tools like pinchers, cutters and grabbers often have an elastomeric grip so robotic hands have a firm grasp and avoid any movement of the tool in a potentially wet environment during surgery.

The materials chosen to build these tools must often be stiff and strong. To meet these requirements, surgical tools for robotics machines are frequently made using a combination of materials which may contain glass or carbon fiber reinforcement for stiffness and the ability for other tools like cameras to travel down the length of the trocar body.

Meeting aesthetic and sustainability requirements

Surgical robotics machines are a large capital investment. As such, they are often lauded as the pride of medical care facilities and even advertised on highway billboards. While they are built to perform intricate surgical maneuvers, they must also impress facility boards, investors and patients. Luckily, a multimillion-dollar, state-of-the-art medical device can be functional and beautiful.

Choosing raw materials that are aesthetically pleasing is important. Manufacturers should consider materials that can be colored or printed to display logos and match existing branding. Popular materials include glossy finishes, UV protection and coloring capability that won’t fade over time. Color is also crucial for mistake-proofing surgeries. Color-coding tools and surgical accessories improve surgical team communications.

One of healthcare’s biggest opportunities to increase sustainability is the volume and treatment of medical waste. Making the right choices about surgical robotics tools can help facilities with their sustainability goals. While medical standards require the tools themselves to be single-use and disposable, the packaging used to keep them sterile can be recycled instead of sent to a landfill. Recyclable packaging solutions are available now to increase sustainability in healthcare facilities. And material innovation is always underway to help support a more environmentally responsible medical industry.

Building surgical robotics machines that withstand sterilization and heat while meeting performance, aesthetic and sustainability requirements is no easy task. When materials are selected thoughtfully with consideration for each piece’s intended function, surgical robotics machines perform surgeries in a high-quality, reproducible manner. They also impress stakeholders while holding up to the wear and tear that naturally occurs in a high-traffic, harsh and demanding healthcare environment.

Josh Blackmore is the global healthcare manager at M. Holland Co. [Photo courtesy of M. Holland]

How to submit a contribution to MDO

The opinions expressed in this blog post are the author’s only and do not necessarily reflect those of Medical Design & Outsourcing or its employees.