Motor technology is often a critical choice for design engineers working on disposable surgical tools — specifically the selection of either a brush DC or brushless DC motor.

Clémence Muron, Portescap

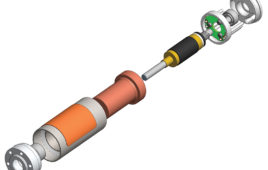

Coreless brush DC motor (Image courtesy of Portescap)

Surgical power tool designers must choose whether to take a disposable or reusable design approach. Design and manufacturing improvements for both brush DC and brushless DC (BLDC) motors have reduced price points while increasing performance, making it possible to achieve a sufficiently low per-surgery tool cost with a disposable design.

Motor performance requirements for single-use tools

While motor performance requirements are similar for reusable and disposable surgical tools, the lifetime and cost requirements are vastly different. A motor specified for a reusable tool may have a lifetime requirement of hundreds or even thousands of surgeries and thus must use premium components and materials. A motor for a disposable tool needs to provide similar performance and often must be available in high volumes and at a competitive price.

When specifying motors for disposable tools, design engineers should consider the possible advantages of conventional brush DC motors over the more advanced BLDC technology. The reliability advantages of BLDC do unfortunately increase costs, often making them unfeasible to specify for a disposable tool. Designers should work with a motor supplier well-versed in both technologies to identify the performance and cost trade-offs.

Brush DC vs. brushless DC motors

If the goal of a new project is to maximize performance and reliability, a design engineer is likely to gravitate to BLDC technology. Brushless technology makes it possible to operate at high speeds (up to 100k RPM) over a long operating life. In BLDC, commutation is achieved without the use of mechanical brushes (i.e., via magnetic Hall sensors or sensorless drive with a brushless motor controller) – so the contact between the motor’s rotating and stationary components is limited to the ball bearings. This means the lifetime of the motor is primarily related to the longevity of the bearing, and the motor can operate at high speed for an extended period.

In a brush DC motor, commutation is achieved through mechanical brushes made of graphite or precious metal, making physical contact with the rotor to complete the electrical connection. The lifetime of the motor is primarily limited to the lifetime of the brushes, with higher speeds leading to premature wear. For a disposable tool, the higher speed may not be an issue given the short lifetime requirement. However, this will depend heavily on the duty cycle and speed requirements of the application.

The design and materials used for a brush DC motor will also affect performance. Most lower-cost brush motors have an iron core, while a coreless motor’s rotor is only composed of a coil and a single shaft. The coreless design offers lower inertia, resulting in better acceleration and efficiency. It also eliminates detent torque (cogging torque), which can reduce rotation smoothness at slower speeds.

For reusable surgical tools, the lifetime and speed requirements often make BLDC the ideal solution. However, for some applications using a single-use design, a brush DC motor can provide an attractive solution.

Clémence Muron is an applications engineer for Portescap, a supplier of motor technology to surgical OEMs.

The opinions expressed in this blog post are the author’s only and do not necessarily reflect those of Medical Design and Outsourcing or its employees.

Photo caption: A coreless brush DC motor (Image courtesy of Portescap)