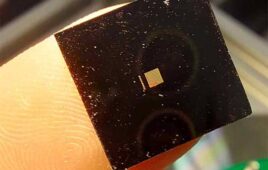

This image shows a keyhole void about to be formed during the metal 3D printing process. (Image from

Carnegie Mellon University College of Engineering)

Researchers have discovered how to predict whether tiny gas pockets will form in 3D-printed products, leading to potential cracks and other failures —- a pivotal discovery that they believe could dramatically improve the 3D printing process.

The scientists used extremely bright, high-energy X-rays to take super-fast video and images of a process called laser power bed fusion, in which lasers are used to melt and fuse material powder together. The lasers, which scan over each layer of powder to fuse metal where it is needed, create the finished product from the ground up. Defects can form when pockets of gas become trapped into these layers, causing imperfections that could lead to cracks or other breakdowns in the final product.

Until now, manufacturers and researchers did not know much about how the laser drills into the metal, producing cavities called “vapor depressions,” assuming that the type of metal powder or strength of laser were to blame. The research shows that these vapor depressions exist under nearly all conditions in the process, no matter the laser or metal. The research also reveals how to predict when a small depression will grow into a big and unstable one that can potentially create a defect.

The team led by researchers from Carnegie Mellon University and Argonne National Laboratory published their work in the journal Science.

“Most people think you shine a laser light on the surface of a metal powder, the light is absorbed by the material, and it melts the metal into a melt pool. In actuality, you’re really drilling a hole into the metal,” said Carnegie Mellon materials science and engineering professor Anthony Rollett in a prepared statement. “We’re drawing back the veil and revealing what’s really going on.”

The research shows that keyholes form when a certain laser power density is reached that is sufficient to boil the metal. This reveals the importance of the laser focus in the additive manufacturing process, an element that has received scant attention so far, according to the research team. Their work could improve quality control in 3D printed manufacturing, added Rollett, a study co-author and co-director of the NextManufacturing Center at Carnegie Mellon.

“For additive manufacturing to really take off for the majority of companies, we need to improve the consistency of the finished products,” Rollett said. “This research is a major step in that direction.”

The research team believes this research could motivate makers of additive manufacturing machines to offer more flexibility when controlling the machines and that the improved use of the machines could lead to a significant improvement in the final product. In addition, if these insights are acted upon, the process for 3D printing could get faster.

“It’s important because 3D printing in general is rather slow,” Rollett said. “It takes hours to print a part that is a few inches high. That’s OK if you can afford to pay for the technique, but we need to do better.”