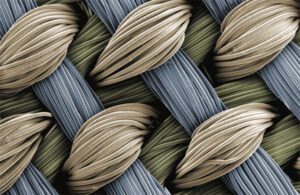

CytexOrtho uses a three-dimensional weaving process to make its ReNew Hip implants. Shown here is a close-up of the woven textiles. [Image courtesy of CytexOrtho]

CytexOrtho is using advanced 3D manufacturing techniques to make absorbable hip implants that could help younger patients delay or avoid hip replacements.

CytexOrtho is developing absorbable orthopedic implants with a unique manufacturing method to help a rapidly growing patient population.

The ReNew Hip implant developer won the inaugural OrthoPitch tech innovation competition at AAOS 2024, beating out more than 40 other nominees.

CytexOrtho co-founder and CEO Brad Estes said the startup has filed its FDA investigational device exemption (IDE) for a Phase 1 clinical trial in the U.S., he told Medical Design & Outsourcing after his recent DeviceTalks Weekly interview. The company plans to seek FDA premarket approval (PMA) after a larger Phase 2 pivotal trial.

DeviceTalks live and in person: Registration is now open for DeviceTalks Boston (May 1-2)

CytexOrtho (incorporated as Cytex Therapeutics) designed the hip implants for people who are younger than traditional joint replacement candidates.

About half of all total hip replacements are for patients under the age of 65, Estes said, with a 40% growth rate for those procedures in patients ages 55 to 64.

There are also double-digit increases in total hip volumes for younger age groups: 25% for ages 45 to 54 and 14% for ages 35 to 44.

Many of those patients — and even some in their 20s — have pre-arthritic disease or less common conditions, with a total hip replacement likely within their next decade.

“Surgeons look at it and go, ‘I’ve got nothing for that patient right now.’ But they need help,” Estes said in an interview with DeviceTalks Editorial Director Tom Salemi and WTWH Media Life Sciences Editor in Chief Chris Newmarker. “One of our surgeons called it benign neglect — they’ll go into the joint, they will relieve whatever is causing the damage, but then they’re stuck with these lesions inside the joint that really don’t have any solutions. And we know that they’re going toward deterioration and degradation. This joint’s going to start falling apart and they’re on that fast-track for a total hip replacement.”

“Those patients were never intended to get a hip replacement, and yet, that’s what’s driving this large market right now, and orthopedic surgeons can’t even keep up with the demand of it,” Estes later continued. “That’s a problem. This is a patient population that definitely needs a solution.”

How CytexOrtho could help delay or prevent hip replacements

CytexOrtho designed its ReNew Hip implants to help patients delay or avoid total hip replacements. [Photo courtesy of CytexOrtho]

“We’re basically targeting those patients who are too early for a hip replacement because they’re young, they’re active, and they’ll wear out their implant multiple times in their lifetime if they want to keep that active lifestyle,” Estes said. “We have technology that can basically restore the surface of their joint.”

To place the implant, a surgeon will first remove damaged tissue from the joint. Then the surgeon replaces that damaged joint tissue with the implant, offering a protective cushion that can be fully absorbed into the body after two years, leaving only the patient’s own tissue.

“We’re restoring both the form — which means the anatomy and the congruity of the joint — but we’re also restoring it functionally, and we’re doing it in a way that’s friendly to the biology in the joint,” Estes said. “People have done that before with with different types of products and different types of materials, but what we’re doing is in a way that is friendly to the cells and tissue development.”

CytexOrtho’s ReNew Hip implants act as cushioning within a patient’s hip joint and is fully absorbed by the body over two years as the patient’s normal tissue replaces it. [Illustration courtesy of CytexOrtho]

“It’s not super common in orthopedics, but it’s used and it’s got a good track record with FDA — it’s something they recognize and something they’re familiar with,” Estes said.

CytexOrtho tried other materials, including nonabsorbable materials, other biologics and silk, but ultimately went with PCL for its safety profile and biocompatibility.

“It absorbs so slowly, it gives the body ample time to make that functional tissue matrix in and around it as it absorbs,” Estes said.

“As cells come in, attach to the implant and then start to make tissue, we’ve shown this tissue to be functional in all our preclinical animal studies, and we’ve taken animal studies out to a year now, which is what FDA demands for clinical trials,” Estes said. “We’ve done that and we’ve shown that as the implant absorbs, we don’t lose the form or the functionality of the joint.”

CytexOrtho’s ‘secret sauce’

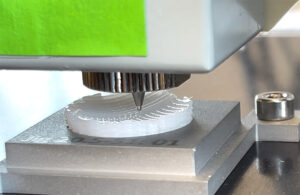

CytexOrtho uses 3D printing and a three-dimensional weaving process to make its ReNew Hip implants. [Photo courtesy of CytexOrtho]

“We’re actually weaving in three dimensions, if you can picture that. It’s really hard to imagine, but instead of just traditional X and Y basket-type weaving, we’re also weaving in that Z or third dimension as well,” he said. “What that does conceptually is by controlling the materials and the spacing in all three of those directions, you can start to dial in the mechanical properties of the tissues you’re trying to replace in your body.”

The weaving materials are multifilament yarns that are several hundred microns in diameter.

“We’ve controlled the sourcing of those and had to manufacture [them]. You can’t just go and order them from Amazon, so we had to figure out how to make those,” he said.

Estes traces the concept back to a 2007 paper published in Nature Materials by his co-founders, Executive Chair Farshid Guilak and VP of Technology Frank Moutos.

“It showed that we could tune this structure to match the native properties of articular cartilage without any compromise of the ability to form tissue in the joint,” Estes said. “And that kind of started us out on our journey with that discovery. That’s kind of the hallmark feature of the implant.”

Advice for other medical device developers

CytexOrtho co-founder and CEO Brad Estes [Photo courtesy of CytexOrtho]

CytexOrtho has funded its work through more than $19 million in National Institutes of Health (NIH) grant funding. While that means the technology went through thorough vetting and validation, “it’s also the absolutely slowest way to do product development.”

It calls for a methodical, marathon approach with a focus on communication, grant-writing, thoughtful deliberation for every decision — and “incredible perseverance.”

“You have to know that you have the technology and your science is solid, but then you just have to keep hammering on it with NIH submissions and if the grant’s good and, and this technology is good, you’ll get it funded,” he said. “It’s an exercise in, ‘I’m going to be super diligent, super perseverant, and we’re going to get this funded, and I’m going to wait you out.’ We were just dogmatic in that approach.”

“It’s got to be your passion. … You just have to be willing to just persevere through solving tons of problems,” he later continued. “And if if you have a dream, and you have the solution for something and you want to make it happen, go for it.”

Related: The best medtech innovations of 2023

Hear more from CytexOrtho co-founder and CEO Brad Estes in the full DeviceTalks Weekly interview below: