Researchers at the Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS) have developed a dielectric elastomer with a broad range of motion that requires relatively low voltage and no rigid components. They published their work recently in Advanced Materials.

The artificial muscles that move soft robots, called actuators, tend to rely on hydraulics or pneumatics, which are slow to respond and difficult to store. Dielectric elastomers, soft materials that have good insulating properties, could offer an alternative to pneumatic actuators but they currently require complex and inefficient circuitry to deliver high voltage as well as rigid components to maintain their form—both of which defeat the purpose of a soft robot.

“Electricity is easy to store and deliver but until now, the electric fields required to power actuators in soft robots has been too high,” said Mishu Duduta, a graduate student at SEAS and first author of the paper. “This research solves a lot of the challenges in soft actuation by reducing actuation voltage and increasing energy density, while eliminating rigid components.”

Duduta co-authored the paper with Robert Wood, the Charles River Professor of Engineering and Applied Sciences, and David Clarke, the Extended Tarr Family Professor of Materials.

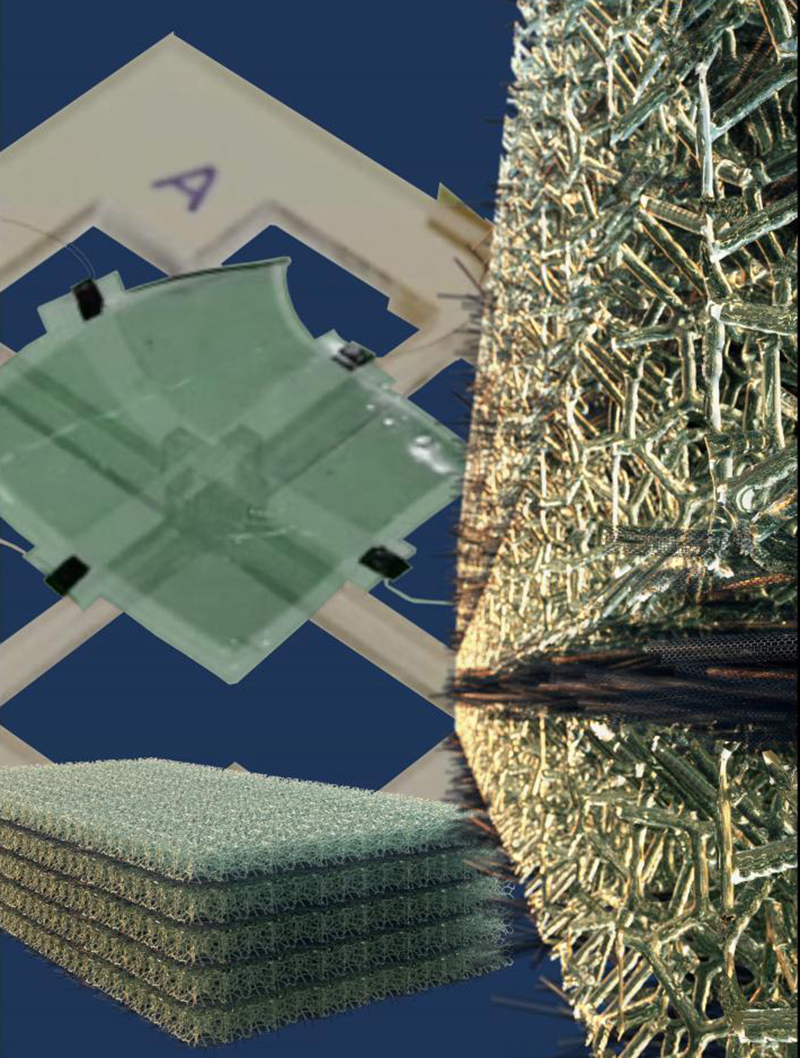

An artificial muscle built from a sandwich of soft, stretchable elastomers and carbon nanotubes electrodes. (Credit: Peter Allen/Harvard SEAS)

In building a new dielectric elastomer, the team combined two known materials that worked well individually—an elastomer based on one developed at UCLA that eliminated the need for rigid components and an electrode of carbon nanotubes developed in the Clarke Lab. The complementary properties of these two materials enabled the new device to outperform standard dielectric elastomer actuators.

Most dielectric elastomers have limited range of motion and need to be pre-stretched and attached to a rigid frame. Starting with an elastomer that doesn’t need to be pre-stretched, developed by researchers at UCLA, the modified materials begin as liquids and can be cured rapidly under UV light to produce paper-thin sheets. They are sticky—like double-sided tape—so they can adhere well to each other, and to the electrodes.

For the electrodes, the team replaced carbon grease, which is typically used as an electrode in dielectric elastomers, with a mat of thin carbon nanotubes. The nanotubes neither increase the stiffness of the elastomer nor decrease the energy density—meaning the elastomer can still stretch and provide significant force. The team fabricated the elastomers one on top of the other, creating a multilayer sandwich of elastomer, electrode, elastomer, electrode and so on. In this way, each electrode gets double usage, powering the elastomer above and below.

This type of actuator could be used in everything from wearable devices to soft grippers, laparoscopic surgical tools, entirely soft robots or artificial muscles in more complex robotics.