Jabil recently announced that it has expanded its additive manufacturing capabilities by adding engineered materials to reinforce its 3D printing capabilities.

Jabil recently announced that it has expanded its additive manufacturing capabilities by adding engineered materials to reinforce its 3D printing capabilities.

The company also says that it plans to adopt more 3D printing solutions to make more highly functional parts for a number of diverse and unique customer applications.

“Jabil is taking advantage of its rich history in materials science innovation to advance the entire additive manufacturing market forward and produce custom materials in weeks – not months,” John Dulchinos, VP of digital manufacturing at Jabil, said. “Our ability to integrate new engineered materials into our ecosystem of 3D printers and rigorous processes will transform a new generation of additive manufacturing applications, including those for heavily regulated industries, such as aerospace, automotive, industrial and healthcare.”

Jabil has also opened a Materials Innovation Center in Minnesota to help deliver complete 3D printing solutions in one facility. The company currently offers polymer formulations, compound development and ISO 9001 Quality Management System certification.

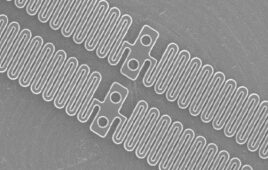

The engineered materials will give customers a quicker approach to prototyping to production that currently available through Jabil. Features on the materials include reinforced, flame retardant, conductive, lubricated, Electrostatic Dissipative and other engineered characteristics. The services with the materials include compounding, extrusion, powder creation and complete system integration on standard, open source platforms that are supported by fused filament fabrication, selective laser sintering and high-speed sintering equipment.

“As an emerging digital manufacturing powerhouse, Jabil is clearing the major obstacles to delivering robust, certifiable, traceable production solutions for additive manufacturing,” Richard D’Aveni, a Dartmouth Tuck professor. “By smoothing interconnecting 3D printing machines, processes and materials across its global additive manufacturing network, Jabil is poised to propel the entire additive manufacturing market forward with speed and agility.”