[Image from the Wyss Institute at Harvard University]

The human skin flexes and stretches to match how our bodies move. Anything worn tight on the skin needs to be made of a flexible material that can also move with the body, like spandex. Incorporating rigid electrical components on or within materials similar to spandex has been challenging in the past because the electronics are unable to flex and creates stress between hard and soft elements.

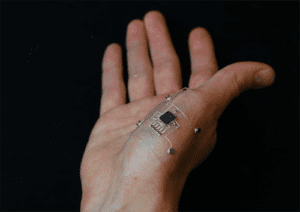

Wyss Institute for Biologically Inspired Engineering at Harvard University researchers have created an additive manufacturing technique for soft electronics called hybrid 3D printing. The method involves combining soft, electrically conductive inks and matrix materials with rigid electronic parts and putting them into a stretchable device.

“With this technique, we can print the electronic sensor directly onto the material, digitally pick-and-place electronic components and print the conductive interconnects that complete the electronic circuitry required to ‘read’ the sensor’s data signal in one fell swoop,” Alex Valentine, the study’s first author and former staff engineer at the Wyss Institute, said in a press release.

The conductive ink is made from thermoplastic polyurethane (TPU). The device uses pure TPU and silver-TPU inks to create a soft substrate with conductive electrodes.

“Because both the substrate and the electrodes contain TPU, when they are co-printed layer-by-layer they strongly adhere to one another prior to drying,” said Valentine. “After the solvent evaporates, both of the inks solidify, forming an integrated system that is both flexible and stretchable.”

During the 3D printing process, silver flakes in the ink align themselves in the printing direction s the flat, plate-like sides are layered on top of each other. The layering improves conductivity with the printed electrodes.

“Because the ink and substrate are 3D-printed, we have complete control over where the conductive features are patterned, and can design circuits to create soft electronic devices of nearly every size and shape,” Will Boley, co-author on the study, said.

When the material is stretched, soft sensors with conductive materials experience changes in their conductivity. The soft sensors are combined with programmable microcontroller chips that process the data from movements and a readout device that is able to communicate that data in a way that users can understand it. The researchers used a combination of printed soft sensors and a digital pick-and-place process that creates a vacuum through an empty printing nozzle that picks up electronic components and plays them on substrate surfaces in a programmable way.

Since electronic components are generally hard and rigid, the researchers used the adhesive properties of TPU to create anchors for the components. Small amounts of TPU ink were placed under each component before attaching it to the soft TPU substrate. The fully assembled devices could then be stretched up to 30% while still maintaining its function.

To test the method, two soft electronic devices were made. The first, a strain sensor, was created by printing TPU and silver-TPU ink electrodes onto a textile base with an added microcontroller chip and attached LEDs. The result was a wearable sleeve-like device that lit up when a user’s arm bent. The second device was a pressure sensor that was the shape of a person’s left footprint. It was created by printing alternating layers of conductive silver-TPU electrodes and insulating TPU that formed capacitors on a soft substrate. A manual electronic readout system created a visual heat map of when a user stepped on the sensor.

“We have both broadened the palette of printable electronic materials and expanded our programmable, multi-material printing platform to enable digital ‘pick-and-place’ of electronic components. We believe that this is an important first step toward making customizable, wearable electronics that are lower-cost and mechanically robust,” Jennifer Lewis, corresponding author of the study, said.

Another team of Harvard researchers recently created fabric-based sensors that moved with the body and could be used in wearables while a Japanese team created electronic tattoos using a home inkjet printer.

The research was published in the journal Advanced Materials and was funded by the Air Force Research Laboratory Materials and Manufacturing Directorate and UES, the Vannevar Bush Faculty Fellowship Program under the Office of Naval Research, a donation from the GETTYLAB and the Wyss Institute at Harvard University.