Titanium sponge (pictured) is a key ingredient for medical nitinol manufacturing. [Photo by Alexey Rezvykh via Adobe Stock]

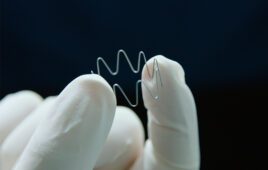

Nitinol — an alloy of nickel and titanium — takes a long, hot journey from the Earth’s crust to the deepest parts of the human anatomy. It starts with ore heaved from deep mines underground or stripped from the soil and refined into titanium and nickel.

To make raw nitinol, suppliers melt pure titanium — in the form of sponge or top-shelf crystal bar — with pure nickel. Titanium has a melting point around 1670°C, while nickel melts around 1453°C. Those are some of the highest melting points among metallic elements. The resulting nitinol has a melting point near 1300°C.

Nickel and titanium must be combined at a roughly 1:1 atomic ratio, which comes out to around 55% nickel and 45% titanium. A nitinol at that ratio would be referred to as nitinol 55.

To be used for medical devices, the resulting nitinol should meet standards set by ASTM International, which requires nitinol to be 54.5% to 57% nickel.

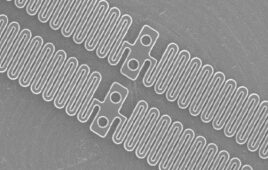

Medical nitinol manufacturing with vacuum melting

Because of titanium’s reactivity at high temperatures, it must be melted in a vacuum or inert atmosphere to minimize the formation of oxide inclusions (more on those later). The two main melting options for making nitinol are vacuum induction melting (VIM) and vacuum arc remelting (VAR). Double-melting is a process that uses both VIM and VAR.

VIM and VAR both satisfy FDA guidance for nitinol and ASTM nitinol standards, so there’s little difference for medical device developers to consider.

But if you’re curious, VAR achieves uniform composition through multiple cycles of melting and remelting, while VIM achieves more uniform composition on the first melt but is only suitable for smaller quantities. For larger quantities, a double-melt process starts with VIM to reach a target composition, followed by a VAR re-melt to combine VIM batches.

Nitinol melters must measure attributes of the nitinol such as grain size, inclusions, mechanical properties, transformation temperatures and certify to nitinol processors and device makers that the nitinol satisfies FDA and ASTM requirements.

Larger oxide inclusions hurt the fatigue durability of nitinol, which could lead to a device breaking inside a patient.

Nitinol allows the Affera Sphere-9 mapping and ablation catheter (now owned by Medtronic) to expand inside the heart to treat atrial fibrillation. [Photo courtesy of Affera]

To measure inclusions, nitinol melters and their customers can polish a sample and inspect the alloy using optical microscopy or scanning electron microscopy at standardized levels of magnification.

Hot forging and hot rolling nitinol ingots

After melting, the molten nitinol cools in a cast to form an ingot. These nitinol ingots can weigh as much as 2,000 to 5,000 pounds.

Nitinol ingots are heated and shaped with hot forging and hot rolling into smaller shapes such as bars, rods and slabs. Making nitinol workable requires temperatures in the temperature range of 800°C to 1000°C.

In our next article, we cover how medical-grade nitinol bars, plates and rods are processed into wire, coils, tubes and sheets for medical device manufacturers.

More about medical nitinol manufacturing and devices:

- What is nitinol and where is it used?

- How Medtronic uses nitinol to improve the structure and effectiveness of heart devices

- How J&J Medtech’s Cerenovus Embotrap stent retriever thrombectomy treats ischemic strokes

- Why Affera’s cardiac ablation technology is worth $1B to Medtronic

- After recall and relaunch, Medtronic wants to go global with its Harmony valve