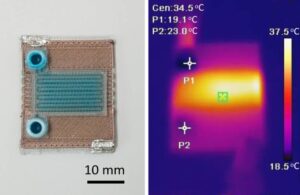

MIT researchers developed a fabrication process to produce self-heating microfluidic devices in one step using a multi-material 3D printer. Pictured is an example of one of the devices. [Image courtesy of the researchers]

Microfluidics have uses in detecting diseases within tiny samples of blood or fluids, like in COVID-19 test kits. The team at MIT believes the technique could someday help rapidly create cheap but accurate disease detection tools.

According to MIT, many microfluidic applications require chemical reactions performed at specific temperatures. More complex devices of this nature have heating elements created in a difficult-to-scale fabrication process. To address this, the MIT team used multilateral 3D printing to create self-heating microfluidic devices with built-in heating elements. The devices can heat fluid to a specific temperature as it flows through microscopic channels within the machine.

With a customizable technique, an engineer could create a microfluidic that heats fluid to a certain temperature or gives a heating profile within a specific area of the device. The team says this low-cost fabrication process requires about $2 of materials to generate a ready-to-use microfluidic. It could be useful in remote regions of developing countries where clinicians may not have access to expensive equipment required for many diagnostic procedures.

Luis Fernando Velásquez-García, a principal scientist at MIT’s Microsystems Technology Laboratories, served as senior author on a paper on this technique. Jorge Cañada Pérez-Sala, an electrical engineering and computer science graduate student, served as lead author.

“Clean rooms in particular, where you would usually make these devices, are incredibly expensive to build and to run,” Velásquez-García said. “But we can make very capable self-heating microfluidic devices using additive manufacturing, and they can be made a lot faster and cheaper than with these traditional methods. This is really a way to democratize this technology.”

The fabrication process to 3D print self-heating microfluidics

The MIT team used a technique called multilateral extrusion 3D printing. In this method, several materials can come through the printer’s many nozzles, building a device layer by layer. The monolithic process produces the entire device in one step on the printer with no need for post-assembly.

Researchers used two materials — polylactic acid (PLA) and a modified version of PLA. The modified PLA includes copper nanoparticles mixed into the polymer, converting insulating material into an electrical conductor. When electrical current goes into a resistor made from the modified PLA, energy is dissipated as heat.

“It is amazing when you think about it because the PLA material is a dielectric, but when you put in these nanoparticle impurities, it completely changes the physical properties,” Velásquez-García said. “This is something we don’t fully understand yet, but it happens and it is repeatable.”

Using a multi-material 3D printer, the team fabricated a heating resistor and printed the microfluidic device. The device has microscopic channels through which fluid can flow, created directly on top in one printing step. Heat dissipated from the resistor warms fluid through the channels within the device. The team also used the printer to add a thin, continuous layer of PLA between the resistor and microfluidic.

The result is a machine registering around the size of a U.S. quarter, produced in just minutes. Channels measure about 500 micrometers wide and 400 micrometers tall and thread through the microfluidic to carry and facilitate chemical reactions. The translucent design of the device means fluid remains visible. According to the MIT team, this helps as processes rely on the visualization or use of light to infer what happens during chemical reactions.

Creating chemical reactors ‘that do exactly what you want’

According to MIT, the prototype created in this process could heat fluid by four degrees Celsius as it flowed between input and output. The team believes the technique could create devices that heat fluids in certain patterns or along certain gradients.

“You can use these two materials to create chemical reactors that do exactly what you want. We can set up a particular heating profile while still having all the capabilities of the microfluidic,” Velásquez-García said.

The team adds the caveat that PLA can only be heated to approximately 50°C before it begins to degrade. According to MIT, many chemical reactions, including ones used for polymerase chain reaction (PCR) tests, require temperatures of 90°C or higher. Also, to precisely control the device’s temperature, researchers would need to incorporate a third material for temperature sensing.

On top of addressing the temperature issue, the team also wants to print magnets directly onto the devices. Magnets could enable reactions that require the sorting or alignment of particles, Velásquez-García says. The team could also use other materials that reach higher temperatures. They’ll continue studying PLA to figure out why it becomes conductive when certain impurities are added to the polymer.

“If we can understand the mechanism that is related to the electrical conductivity of PLA, that would greatly enhance the capability of these devices, but it is going to be a lot harder to solve than some other engineering problems,” Velásquez-García said.