If you’ve looked at resin 3D printing in the past and aren’t currently taking advantage, it’s worth another look.

By Chris Danek, Bessel and Trion Concepts

3D printing has long been a staple for rapid prototyping of medical devices. Recent advances in additive manufacturing with resin cure systems have greatly expanded the capabilities available — in many cases, right on the R&D engineer’s desktop.

We now have resins that behave similarly to engineering thermoplastics like ABS, polycarbonate and even elastomeric materials. And print speeds and resolutions have increased dramatically.

Together, these advanced materials and improved printing mean resin printers can produce highly functional parts and high-fidelity prototypes to iterate designs for short-run production and as a bridge to injection-molded tools. Let’s explore how medical device manufacturers are using these advancements to innovate the traditional design and production process.

Using advanced materials to create the next generation of removable dental veneers

Trion Smiles, shown here mounted on a resin-printed typodont (a model of the upper teeth), are designed and 3D-printed from a high-resolution scan taken in the dentist’s office. [Photo courtesy of A. Gutierrez]

Use case: Trion Concepts Inc. is printing removable dental veneers using a high-performance proprietary biocompatible dental resin material with carefully optimized strength, toughness and rigidity. The accuracy of the design starts with a high-resolution 3D scan of the patient’s teeth at the dentist’s office. Creating personalized designs that are highly aesthetic, fit comfortably, and can be worn confidently in social settings requires very thin 3D printed parts. This is only possible with recent advances in resin and print resolution with 3D printers from companies like SprintRay and LuxCreo.

Medical device prototyping and production parts

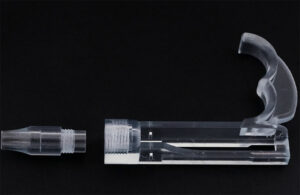

Fulmer Instruments surgical instrument handle switch plate printed in Somos Watershed Black XC11122 Resin from Stratasys on a 3D Systems Viper si2 printer (left). Repliform Inc. nickel and copper plated interior surfaces (right). [Photos courtesy of A. Gutierrez]

Use case: Medical device startup Fulmer Instruments printed fully functional handle prototypes in ABS-like resin. The emergence of high-performance engineering resins in recent years is a game-changer. Because the material is functional and simulates the performance of injection molded parts, it allowed for high-fidelity pilot testing to derisk design verification. The highly aesthetic parts allowed usability testing and more rapid iteration of the form factor, weight and balance of the handheld instrument than injection molded parts would afford. Electrical shielding is a common challenge for electromedical devices. Fulmer Instruments worked with Repliform Inc. on metal plating the inside of 3D-printed parts to evaluate this shielding strategy with pre-scan electromagnetic compatibility and electrostatic discharge testing. (Pro tip: Material extrusion parts have inherent plating challenges caused by poor porosity. Resin-printed parts bypass those challenges.)

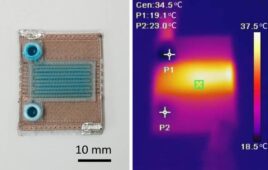

These catheter parts from Sirius Engineering were highly cosmetic and with fully functional fine threads “as printed” without secondary operations. Printed on the Stratasys Neo 450s printer in high definition mode in Watershed 11122XC resin from Stratasys. [Image courtesy of the W.M. Keck Center for 3D Innovation]

Use case: Sirius Engineering needed sets of two parts complete with intricate threads for an urgent catheter build. The parts were a challenge for desktop resin 3D printers: the variation in wall thickness near critical features caused defects during curing, and the fine threads designed to create a fluid-tight assembly required post-printing threading operations with tap and die. Moving to an industrial system eliminated the printing defects and need for threading operations.

In both the Fulmer and Sirius case studies above, state-of-the-art industrial additive manufacturing systems had the resolution to create functional parts with precision, surface quality and speedy delivery.

Is additive manufacturing ready for production parts? In certain cases, resin printing can make sense. Recent increases in the precision of 3D printing and the engineering performance of available resins make this a viable path for capital equipment parts with complex geometries. Specific examples where this has worked well include optomechanical mounts and fluid manifolds with good chemical compatibility for diagnostic instrumentation.

Resin-casting silicone parts using 3D-printed molds

Cast silicone cover installed on switch plate. [Photo courtesy of A. Gutierrez]

Use case: Fulmer Instruments prototyped an elastomeric activation switch cover for a surgical instrument handle using 3D-printed molds to cast silicone parts. An elastomeric part is desirable for tactile feedback and sealing in this application. Silicone performed better than thermoplastic urethane because it doesn’t require a mold release and tolerates greater elongation during demolding to prevent part tearing. As a designer, you’ll need to apply casting design rules to your part design, paying special attention to hard-to-mold features like undercuts, which are protrusions or indentations on the part relative to the direction the mold is separated after casting.

Mold design for cast silicone parts, illustrated in this CAD rendering of a four-piece mold design for Fulmer Instruments’ cast silicone switch cover. Left: One of the mold pieces is hidden to show the central core and its square alignment features. Right: This mold has been designed with one injection port and one vent, visible on top of the mold. [Image courtesy of A. Gutierrez]

- Design the mold for part removal: Using your solid modeling software, create the mold by subtracting your part from a solid block. Split the block into two or more pieces that will allow you to de-mold the part and place the mold parting lines on acceptable surfaces. Here’s a pro trick: you can insert rigid parts in the mold to create overmoldings. This worked great on the Fulmer Instruments project.

- Create alignment features: While round pins and holes work great for machined molds, we’ve had great success with square pegs and square holes because when properly oriented to the build direction, they reproduce well. This helps make more accurate parts and to prevent flash.

- Design for injection: After you have mixed the resin and degassed it under vacuum, you need to get it into the mold. The best way to do this is using a syringe. Instead of putting a pouring cup in your mold, include a luer taper for resin injection.

- Vent the mold: Remember to include vents to allow gases in the mold gates and cavity to escape for proper mold filling.

- Clamp during casting: You can use rubber bands or carpentry quick-release clamps to fixture the mold during casting.

You can use these tips for silicone casting to cast other materials. Just pay special attention to mold release and part demolding, which can be much more challenging with thermoplastic urethanes and rigid thermoplastic parts.

Today’s 3D-printing resins offer a wide range of engineering performance. This, coupled with cost-effective high-resolution printers, leads to many more applications for resin printing in medical devices. If you’ve looked at resin printing in the past and aren’t currently taking advantage, it’s worth another look.

Chris Danek is the CEO of Bessel and CEO of Trion Concepts Inc. [Photo courtesy of Danek]

How to submit a contribution to MDO

The opinions expressed in this blog post are the author’s only and do not necessarily reflect those of Medical Design & Outsourcing or its employees.