Tony Holtz, Proto Labs

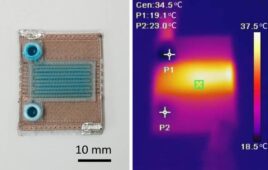

Secondary processes following stereolithography can yield clarity in microfluidic designs. [Courtesy of Proto Labs]

Faster and smoother

New printer technologies, such as HP’s Multi Jet Fusion have enabled prototyping and parts building using thermoplastic nylon powder. The process allows faster build times, improved feature resolution, and consistency of mechanical properties.

The technology uses inkjet array to selectively apply fusing and detailing agents across a bed of nylon powder, which is fused by heating elements into a solid. After each layer is built, a coating of the powder is distributed and the phase continues until the part is complete.

The unique way in which Multi Jet Fusion builds parts results in consistent mechanical properties along all directions of the part’s geometry. If a part has key features on multiple surfaces and requires uniform mechanical properties, Multi Jet Fusion is the way to go. The 3D printer can generally result in a smoother surface finish than SLS. Feature resolutions of 0.020 in. are possible using MJF as where SLS has 0.030 in.

Multi Jet Fusion does have some limitations, Currently, the printer can only offer parts built in Nylon 12. These parts come off the platform as gray, but can be dyed black for consistent coloring. Further, the build envelope is slightly smaller than SLS, at 14.9 in. by 14.9 in. by 11.1 in versus 19 in. by 19 in. by 17 in. seen in SLS.

Clearer and brighter

When creating a microfluidic part for a medical device, or a lens, clarity of material is a key step that usually requires a special build. Usually, the substrate is built of a sheet of clear acrylic that can provide a finished surface with minimal polishing. These down faces won’t have the support structures typically required when using SL, so these down-facing surfaces will have your highest clarity. The up-facing surfaces would have the next best finish followed by any vertical surfaces. To provide optimal clarity to additional faces that may have support structures, the surfaces can then sanded down and polished to remove any visible layers on flat or vertical surfaces. For lenses and some other clear parts, a clear urethane coating can also improve clarity, although this step is not recommended for microfluidics.

Post-production is the time to improve color and cosmetic appearances. In some cases, the 3D printed parts can be treated to resemble injection molded parts. Altering part color can be done by applying colored dye, custom painting, or soft-touch paint to SL and SLS parts. A dye is generally going to be less expensive and faster than paint. Dying can also yield either opaque or transparent results if the part requires.

Tony Holtz is a technical specialist at Proto Labs (Maple Plain, Minn.).

Visit Proto Labs at Booth 103–104 at DeviceTalks Boston on Oct. 2