The personalization of physical medical equipment has posed a challenge – but not any more, thanks to 3D technology.

Andrei Vakulenko, Artec 3D

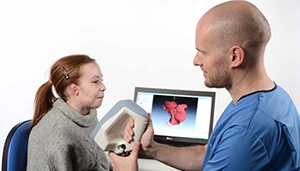

The Royal Hospital for Sick Children (Edinburgh, Scotland) has successfully turned to 3D technology to treat children with microtia, an abnormal smallness of the ear. In this case, clinical nurse specialist Kerr Clapperton is using the Artec Spider to scan patient Ellie’s ear in Artec Studio. [Image courtesy of Artec 3D]

Of course, it has long been easier to tailor the actual prescription of medication to a patient’s needs based on their symptoms. However, the personalization of physical medical equipment has posed a challenge. Handheld 3D scanners (such as the ones Artec 3D makes) have provided a way to overcome this hurdle, especially for rarer diseases and physical ailments. This technology is helping to further push forward this new wave of personalized healthcare.

Cutting medical costs and saving time with 3D scanning

While the history of 3D scanning and printing dates to the 1980s, it’s the recent advancements that are demanding the world’s attention, growing to a $4.1 billion industry, as reported by a Wohler Report.

Part of this growth can be attributed to the fact that within the medical field 3D technology is representing an economically attractive alternative to many traditional medical practices from prosthetics to plastic surgery. With the cost of 3D technology dropping, it is now more financially accessible to doctors, allowing them to implement new practices that address the overall rising cost of healthcare.

3D scanning technology is also becoming a much easier process for many doctors as well. For example, doctors can use a 3D scanner to scan a child’s leg to create an exact replica for a prosthetic. Whereas before, children would need to sit still for a while so a molded cast could be made of a child’s leg. 3D scanning also allows doctors to start and stop a scan, picking right back up where they left off, making the process much easier for both the patient and doctor.

The financial benefits that 3D technology provides can be clearly seen in the treatment of patients suffering from eye cancer and in need of facial prosthesis. The 3D-printed prosthesis can be printed at a fraction of the traditional estimated $10,000 and within weeks. Patients can also avail from a prosthesis that more accurately matches their skin tone and facial details due to a 3D scan of the unaffected area being used to create a mirror image and prosthesis.

Creating customized treatments for rare ailments

In addition to the financial benefits that 3D technologies afford, they are also helping with lesser-known ailments. For example, in Scotland, the Royal Hospital for Sick Children has successfully turned to 3D technology to treat children with microtia, an abnormal smallness of the ear. An estimated one out of 6,000 infants are born with this condition. Traditionally, a clear acetate is used to take a 2D tracing of the normal ear. Using the tracing, cartilage from the patient’s ribs is used to carve an ear shape. Using a handheld 3D scanner, doctors are now able to 3D scan the unaffected ear and 3D print the scan to use as a reference, instead of the tracing. The hope is to one day use a 3D scan of an ear to print a polymer surface for stem cells to grow so that an ear can be created using tissue engineering.

3D scanners can help change a whole process or help a particular patient with a particular problem.

For example, Graves’ disease – or Basedow’s disease – affects about 0.5% of males and 3% of females with exophthalmos (protrusion of one or both eyeballs) being one of the common symptoms. If the disease progresses it may require surgery, which has a risk of possible damage of the tendinous tissue of the muscle that elevates of the upper eyelid. This can impede the eye from properly closing, making it extremely difficult for the patient to rest at night. Digital Maison, a 3D scanning and printing service provider in Italy, was tasked with helping one such patient. A handheld 3D scanner was used from the comfort of the patient’s home to accurately, digitally capture the patient’s face. 3D software measurement tools revealed deviations in the shape of the face depending on the patient’s position (lying and sitting): the skin on the softest parts, cheeks primarily, can move up to 5 mm if the patient goes from lying to sitting. A 3D model of the mask was created that would perfectly fit the patient’s face, block light and completely close the eyelids underneath.

Expanding 3D scanning medical applications with artificial intelligence

The one barrier that has traditionally withheld the adoption of 3D scanners in the medical field is the need for time-consuming training. While it would be useful for a plastic surgeon to be able to utilize a handheld 3D scanner to scan a patient’s features and then digitally alter them to show the results that can be expected, this is not part of standard medical training. However, developments in artificial intelligence (AI) are democratizing the 3D scanning process.

3D scanners can now incorporate new technologies like the NVIDIA Jetson AI supercomputer to become more intuitive and intelligent. Already, advanced scanners and software are incorporating autopilot features that are making it easier to achieve a professional scan. The next step is the creation of scanner that can understand what it is scanning and be able to “think” in terms of parameters. An example would be using an intelligent scanner to scan the shape of a body to examine the curvature of a patient’s spine. If this were to be adopted by a school, a nurse could use the technology on students and flag results that may require special medical attention and diagnosis.

This future is not that far away. There are endless ways that 3D scanning can be used within the healthcare space. However, it is easy to see that it is already changing the way we approach ailments and the creation of customized treatments. Medical professionals that are willing to be innovative in their approaches and adopt 3D scanning, will be ahead of the curve.

Andrei Vakulenko is chief business development officer at Artec 3D (headquartered in Luxembourg, with subsidiaries in Santa Clara, Calif., and Moscow, Russia.).