Mechanical engineering professor Michael McAlpine shows off an LED that was 3D printed in curved glass. [Photo by Frank Wojciechowski/Princeton University]

The U.S. Patent Office in February issued a patent for “3D printed active electronic materials and devices.” The patent covers work that McAlpine, a University of Minnesota mechanical engineering professor, and Yong Lin Kong, a University of Utah mechanical engineering professor, conducted when they were at Princeton University. Princeton is the patent’s assignee.

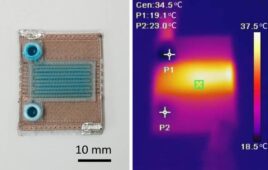

The patent describes a 3D printing method to produce active electronics made of semiconducting materials. Everything is made through the printer. “These disclosed semiconductors may provide a multitude of end uses, such as wearable displays and/or continuous on-eye glucose sensors,” the patent said. “These devices may also include a range of functionality, from including quantum dot light-emitting diodes (QD-LEDs), MEMS devices, transistors, solar cells, piezoelectrics, batteries, fuel cells and photodiodes.”

The patent notes that “integration of electronics on otherwise passive structural medical instruments such as catheters, gloves and contact lenses are critical for next-generation applications such as real-time monitoring of physiological conditions.”

In 2014, the research team published an article in the journal Nano Letters about 3D printing quantum dot-based light-emitting diodes (QD-LEDs) onto a curved surface such as a contact lens. The printing involved seamless interweaving of five different materials, including emissive semiconducting inorganic nanoparticles, an elastomeric matrix, organic polymers used as charge transport layers, solid and liquid metal leads, and a UV-adhesive transparent substrate layer.

3D printing semiconductors opens the possibility of directly incorporating smart functionality into soft, complex three-dimensional biomedical devices, McAlpine recently explained to Medical Design & Outsourcing. Such soft devices, he said, are often incompatible with microfabrication processes, which are limited to 3D and involve the use of harsh chemicals. Conductors are also passive, “dumb” electrodes that only relay information, while semiconductors are “smart,” able to switch, amplify and “think.”

“This opens up the possibility of incorporating smart electronics into biomedical devices such as brain interfaces for communicating with neurons or optogenetic devices such as 3D printed LEDs and photodiodes to stimulate them, sensor tattoos which can directly printed onto the body, cardiac devices which can regulate beating at low power, and ‘bionic’ devices,” McAlpine said.

3D printing semiconductors could become a big business, too. 3D printed electronics could be the next high-growth application for product innovation, with market size expected to reach $1 billion by 2025, according to Deloitte.

McAlpine is among a group of researchers worldwide who have been pioneering custom-built 3D printers that go beyond the capabilities of printers presently on the market. Think software-backed printing on an XYZ platform with multiple materials at once at scales ranging from nano to macro levels.

McAlpine has been able to entirely print devices, including electronics. While at Princeton, he garnered attention for 3D printing an ear out of living cells, while printing an antenna inside the ear at the same time. Earlier this year, McAlpine and his colleagues announced 3D printed tiny stretchable electronic sensory devices that could enable bionic skin for surgical robots – or a new class of wearables directly printed onto human skin.

In the latest advance out of the McAlpine Research Group, the research team took MRI scans and tissue samples from three patients’ prostates, tested the tissue and then used customized silicone-based inks “tuned” to precisely match the mechanical properties of each patient’s prostate tissue. The result as custom-built organ models that looked and felt like the real thing, with integrated sensors help surgeons train.