The move to cloud-based product design tools represents a transformational change, including for medical device creators.

Darren Garnick, Onshape

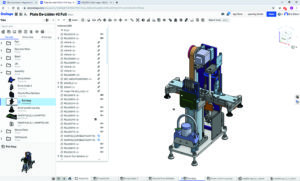

Formulatrix, which develops laboratory automation technology for pharmaceutical R&D, is using cloud CAD to enable real-time collaboration between its design teams in the United States and Indonesia. Pictured above is a component of a refrigerated machine that uses a robotic microscope to rapidly analyze thousands of protein crystals much faster than the human eye. [Screenshot courtesy of Formulatrix]

At the same time, the CAD industry experienced another major platform shift, migrating from cost-prohibitive proprietary computer systems (CAD companies controlled both the hardware and software) to far more affordable Windows PCs. This was the “democratization of CAD,” making the technology available to startups and smaller companies that previously could not access it.

Three decades later, we are again experiencing a transformative change in the world of product design — the move to cloud-based product development tools. Although most industries moved their business-critical tools online years ago — e.g. HR software, CRM, accounting, marketing, etc. — most hardware engineers have been stuck using an installed file-based CAD system tied to a single work computer.

Late adopters or not, product development teams are now finding the advantages of cloud-based design tools hard to ignore. By using a CAD and data management system built on a cloud database architecture, multiple engineers can now simultaneously work on the same CAD model and share their progress with project managers or external partners in real time, versus emailing static files back and forth and waiting for feedback. Teams can instantly access their work on any computer, tablet or phone anytime without the restrictions of software licenses tied to specific hardware. In short, cloud CAD allows companies to spend less time worrying about IT issues and more time on innovation.

German biotech startup BellaSeno designs the external structure of its 3D-printed breast implants with cloud-based CAD tools. [Image courtesy of BellaSeno]

Here are a few examples of medical device companies designing products in the cloud:

- Loop Medical (Lausanne, Switzerland) is developing a new “painless” and minimally invasive device to extract blood from the capillaries just below the skin versus conventional methods that collect blood from the vein. “Onshape’s workflow is really smooth and it’s much easier to share our work and move on to the next task,” said founder Arthur Queval. “As the CEO, I can always see the status of a design and comment or address problems in real-time.”

- BellaSeno (Leipzig, Germany) is seeking to develop a safer alternative to silicone breast implants using a bioresorbable polymer already used in FDA-approved and CE-marked products for other medical procedures. “We’re developing more than 150 different implant sizes and profiles to choose from that fit every possible body type,” said biomedical engineer Sara Lucarotti. “Using Onshape’s configurations feature, I was able to plug in all the measurements and automatically generate 150 CAD models in less than an hour.”

- Formulatrix (Bedford, Mass.) develops laboratory automation solutions for pharmaceutical companies and academic research institutions. The company is using Onshape for designing a robotic microscope that more rapidly analyzes the structure of protein crystals that are critical for disease research. “We were impressed with the collaborative capabilities of a cloud-based CAD program,” said Heinrich Köchling, director of worldwide engineering. “We spend a lot of time with our team in Indonesia on video conference calls, and the ability to have multiple people on different sides of the world work simultaneously on our designs is very powerful.”

- Thinklabs Medical (Centennial, Colo.) has developed a digital stethoscope that amplifies heartbeat sounds more than 100 times the audio levels generated by traditional hollow-tube stethoscopes. “3D printing liberates the design of our products, and Onshape in many ways liberates our production people to be very creative,” said CEO Clive Smith. “We’re no longer tied to one computer. Everyone can just pick any computer and work when they need to. Onshape makes our production process much more efficient.”

While many of the comparisons between different file-based product development software weigh specific CAD features and functionality, cloud-based Onshape also has a heavy focus on improving processes. A comprehensive edit history allows CAD users to revert to any prior stage of a design, encouraging teams to take creative risks. In addition, there are regular automatic software updates — bug fixes, new features and enhancements — released every three weeks in the cloud. Unlike with file-based CAD and data management systems, the cloud upgrades require no installations, have no software incompatibility issues and result in zero downtime.

Darren Garnick is the content director for Onshape, a cloud-based product development software company based in Cambridge, Mass.

![A photo of the Medtronic GI Genius ColonPro polyp detection system flagging a potential sign of colon cancer during a colonoscopy. [Photo courtesy of Medtronic]](https://www.medicaldesignandoutsourcing.com/wp-content/uploads/2024/04/Medtronic-GI-Genius-doctors-268x170.jpg)