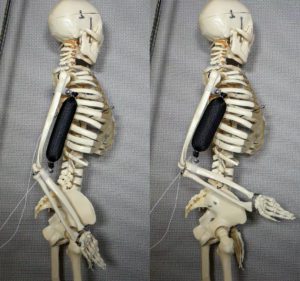

The artificial muscle in use as a bicep lifts a skeleton’s arm to a 90 degree position. [Image from Aslan Miriyev/Columbia Engineering]

Researchers at Columbia Engineering in the Creative Machines lab developed the one-of-a-kind artificial active tissue that has intrinsic expansion that does not need external compressors or high voltage equipment that other artificial muscles need. In addition to expanding to 15 times larger than natural muscle, it can also lift 1,000 times its weight.

Before this research, soft artificial muscles were hard to replicate because different materials didn’t have the properties required for high actuation stress and high strain. Other soft actuators that are currently in use are made using pneumatic or hydraulic inflation of elastomer skins. External compressors and pressure help robots more and work independently.

“We’ve been making great strides toward making robots minds, but robot bodies are still primitive,” Hod Lipson, professor of mechanical engineering, said in a press release. “This is a big piece of the puzzle and, like biology, the new actuator can be shaped and reshaped a thousand ways. We’ve overcome one of the final barriers to making lifelike robots.”

Soft robots are used to mimic the natural motion of the human body like grasping and manipulation in medical applications. Researchers at the Massachusetts Institute of Technology also recently created a soft robot made mostly out of water that could safely grasp objects.

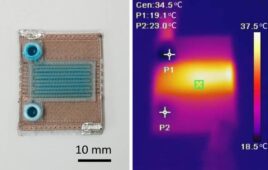

A silicone rubber matrix with ethanol distributed throughout in micro bubbles was used in the Columbia Engineering artificial muscle to reach an actuator with high strain and high stress while also having low density. The elastic properties and different volume chances allowed for the material to be easy to make at a low cost while also being an environmentally-safe material.

The muscle is 3D printed into a specified shape and gets electrically actuated with a thin resistive wire and low-power. It is then tested in different robots to test its expansion-contraction ability where it was shown to expand up to 900% when heated electrically to 80ºC. It could perform a number of motion tasks using almost any design when controlled through computers.

“Our soft functional material may serve as robust soft muscle, possibly revolutionizing the way that soft robotic solutions are engineered today,” Researcher Aslan Miriyev said. “It can push, pull, bend, twist, and lift weight. It’s the closest artificial material equivalent we have to a natural muscle.”

The researchers plan to build upon the muscle development to include more conductive materials to replace the wires and speed up muscle response times. They also hope to incorporate artificial intelligence to learn muscle control.

The research was published in the Nature Communications journal and was funded by Columbia University and an Israeli Ministry of Defense grant for 3D printed robotics.